Services

|

[Technology Before and After - powder and green technology improvement examples] [All About Powder Technology - Free consultation by professionals [Global Marketing Service - Equipment marketing service for manufacturers] [Supply chain system - "BI-MODE" B to B Supply chain & E-Commerce] [B to B/C shopping mall - "Buy NOW" International BUY-DIRECT E-Commerce Service] |

|---|

[Powder Processing Service in Chicago - laboratory instruments by Tsutsui / NBC Meshtec, MITSUMI Iris Valve "Choke Valve" by MITSUMI Technical, air classification by NISSHIN, MATSUBO, wet scrubbing and dust removing by ACO, spray drying by FUJISAKI ELECTRIC ]---- toll service or rental available

Service Example of particle/powder size adjustment

1) Polyester color toner to be classified to 3 fractions (Fine/middle/coarse) at 1 time cut

2) Nickel(metal) or ceramics powder to be classified below 1.5 micron

3) Calcium Carbonate to be classified below 3 micron

4) Remove fine dust below 5 microns from plastics, metal powder

5) etc.

Micro Vibro Sifter M-3T (with/without Nafitec) 500,212,125,106,90 microns opening wiremesh |

V-mixer VM-2 (2 liter vessel) |

ABD-100 to measure Angle of Repose Bulk Density Dispersion of powder |

Manual type MITSUMI Iris Valve "Choke Valve" |

|---|---|---|---|

Automatic type MITSUMI Iris Valve "Choke Valve" |

|

FUJISAKI ELECTRIC Spray Dryer MDL-050 |

MATSUBO ELBOW-JET EJ-L3 |

NISSHIN TURBO-CLASSIFIER TC-15NS / TC-25M |

ACO Double Scrubber WDS2.5 for fine powder dust removal |

ACO Wet Scrubber WS-03 for odor/metal debris removal |

ACO CFS100 (dust remover) |

Cilas 930L Laser (0.2-500 microns) |

Multisizer II at laboratory |

Hitachi oil free compressor |

Sieve/sifter, Air Classifier & Dust Remover available in laboratory (Chicago)

| Manufacturer & Equipment | Model | Minimum Required Amount | Maximum Diameter of Feed Particles | Target PSD, Cut point, objectives | EDS, Questionnaire or service application form |

|---|---|---|---|---|---|

| Micro Vibro Sifter (Tsutsui) | M-3T | 100g | 1-5mm | 500,212,125,106,90 microns - see difference between with/without Nafitec | |

| V-Mixer (Tsutsui) | VM-2 | 1000 ml (50-100%) | any dry powder | powder blending in desk top scale | |

| ABD-100 (Tsutsui) | ABD-100 | 100g | any dry powder | Powder characteristics (angle of repose, bulk density, dispersion) | |

| Nisshin Turbo-Classifier (air classifier) | TC-15NS | 2 kg (about 4 lbs) | 500 microns (35 mesh) | 0.5-100 microns Feed rate: below 22 lbs/hr | Pdf file (62kb) Word file |

| Nisshin Turbo-Classifier (air classifier) | TC-25M | 9 kg (20 lbs) | 500 microns (35 mesh) | 0.8-100 microns Feed rate: below 110 lbs/hr | Pdf file (62kb) Word file |

| Matsubo ELBOW-JET (air classifier) <Chicago/Japan> |

EJ-Labo-3 | 2 kg (about 4 lbs) | 500 microns (35 mesh) | 0.5-50 microns, 3 products at 1 cut | Pdf file (70kb) Word file (80kb) |

| ACO Wet Scrubber / Double Scrubber (single - 10 microns, double - 1 micron or coarser) |

WS-03 /WDS-2.5 | Gas/air | Gas/air | Mist/odor/vapor/fine powder removing from exhaust gas (for PM2.5) | Please use inquiry form. |

| ACO Jet Separator (dust remover) | CFS-100 | 500g (about 1 lbs) | 5-10mm | Dust removing from pellet | Pdf file (62kb) Word file (76kb) |

| FUJISAKI ELECTRIC Spray Dryer (spray drying) | MDL-050L | 2 kg (about 4 lbs) | In slurry | Spray drying in micron order, spheridizing, deagglomeration | Pdf file (71kb) Words file (138kb) |

| MITSUMI Iris Valve "CHOKE VALVE" (valve) | MFV-100 MFV-150 MFV-200 MFV-300 | Please use inquiry form. |

|||

| Cilas 930L (laser type particle size analyzer) | Cilas 930L | 1-2g /sample | 500 microns | Measuring particle size | Pdf file (333kb) |

[ Powder Processing Service in Japan - Cryogenic grinding service by OSAKA Gas Liquid

|

Cryogenic grinding is a technique that uses liquefied nitrogen scooled to an ultralow temperature (−196℃/-320 degree F) to freeze and grind various materials including resins and foods. By using liquefied nitrogen produced by an affiliated company in the same group, we can conduct low-cost and highly efficient grinding |

|---|

1.Any soft materials such as plastics and rubber, as well as foods containing oil or moisture, can be easily ground.

2.By minimizing thermal alteration and oxidation during grinding, cryogenic grinding transforms materials into powder that retains their initial properties (such as a resin’s molecular structure or a food’s flavor).

3.By optimally adjusting the grinding and temperature conditions, we can produce powders that satisfy various customer requirements.

Osaka Gas Liquid Co., Ltd. Cryogenic Grinding Center (plastics factory) 4 Chikko Hamadera-cho, Nishi-ku, Sakai-shi, Osaka 592-8351, Japan (Within Senboku LNG Terminal I) TEL: 072-268-3171; FAX: 072-268-0019 E-mail ⇒ This factory has a series of powder processing equipment and various analytical instruments including our own cryogenic grinding system, Linrex Mill. The factory handles any types of grinding requirements, such as crushing, drying, separation and mixing with its abundant experience and excellent technology.

| Plastics | Food | ||

|---|---|---|---|

| Material | Particle size | Material | Particle size |

| 12 Nylon | 90% below 150 microns(100 mesh) | Sesame seeds | 85% below 250 microns (60 mesh) |

| 6 Nylon | 90% below 150 microns (100 mesh) | Coffee beans | 99% below 38 microns (400mesh) |

| Polyester | 90% below 106 microns (140 mesh) | Kelp | 98% below 75 microns (200 mesh) |

| Polyurethane | 90 % below 500 microns (35 mesh) | Green Tea | 95% below 45 microns (325 mesh) |

| Polyurethane | 90% below 150 microns (100 mesh) | Almond | Good flavor and texture |

| EVA | 70% below 300 microns (50 mesh) | Soy | 99% below 26 microns (500 mesh) |

| Bio Plastics | 50 -500 microns (300 to 35 mesh) | ||

Osaka Gas Liquid Co., Ltd. Cryogenic Grinding Center (food factory)

3-7 Takasago, Takaishi-shi, Osaka 592-0001, Japan

TEL: 072-269-2981; FAX: 072-269-2982

⇒ This factory complies with hazard analysis critical control point (HACCP), designed with many innovations to prevent complex contamination (such as separation of general areas and clean areas). The factory is kept in a sanitary condition by implementing every possible measure to ensure an excellent level of hygiene.

★ Cryogenic grinding service request form (EDS) - Pdf file (32kb),

Word file(44kb)

★ Cryogenic grinding service brochure can be downloaded in - Pdf file(2,878kb).

Questionnaire is available at the bottom of this page.

★ OSAKA GAS LIQUID Cryogenic grinding service - Pdf file (32kb),

Word file(44kb)

★ MATSUBO Turbo-Mill (mechanical pulverizer) - Pdf file(49kb),

Word file(78kb)

★ MATSUBO Crack-U-Lator (granulator/pulverizer) - Pdf file(55kb),

Word file (79kb)

★ Nisshin Engineering (jet mill, air classifier, closed circuit system) - Pdf file (31kb),

Word file(44kb)

★ Cilas 930L (Laser method particle size distribution, wet, 0.2-500 microns)

★ Coulter Multisizer II (Particle counting type particle size distribution)

★ Cilas 1190 (Laser method, particle size, dry) - in Wisconsin state

Test and Custom Processing Service ORDER FORM (EDS)

In order to assist you in testing and/or custom processing your material in USA, we need further detailed information on your material and material specifications.

Please DOWNLOAD our Engineering Data Sheets(EDS for short) for our Testing and/or Custom Processing Services.

Please complete the form as much detailed as possible and send this EDS to AAAmachine, Inc. by Fax at 1-847-376-3530.

If you have any questions or are having difficulty filling out the EDS, please contact us and we will do our best to assist you.

* EDS (pdf file) DOWNLOAD EDS (Word file) DOWNLOAD

EDS (Word file) DOWNLOAD![]()

Once AAAmachine receives the completed EDS, we will recommend the best equipment for the job and prepare a service quotation to include an estimate for the time required to complete the service.

For Questions please call: 1-800-996-0070, or contact us.

AAAmachine, Inc. SERVICES - Powder processing services, parts supply

AAAmachine, Inc's powder processing service provides testing and custom powder processing service that offers timely services in USA ranging from laboratory test, performance comparison, toll manufacturing and measuring analysis. AAAmachine, Inc. is able to produce large-scale toners by cooperating with partners/equipment manufacture in foreign countries.

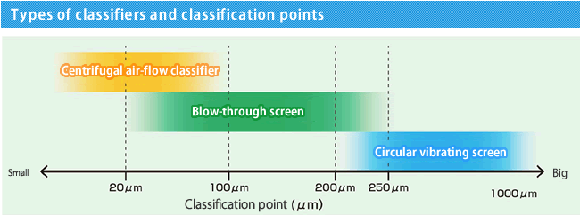

From mm order to the submicron level, from foods, metals, rocks, slag, toners, and carbon to powder coating, and from heat-sensitive to abrasive powders, AAAmachine handles custom classification of every type of material.

AAAmachine meets all needs for manufacturing ultra-fine powders, attaining extremely narrow particle size distribution. And by utilizing a world-class classifiers, it can handle classifying various powders from mm order to submicron/nano-meter level.

With its cutting-edge AAA rating powder processing technology, AAAmachine meets all the customers' needs. A world class powder measuring technology is also available. A world class precise measurements and an extraordinarily experienced and capable staff are the keys to the Company's success in this field.

⇝ Questionnaire for unique powder handling equipment is as follows.

Inquiry

Please feel free to contact us from the following