AAAmachine, Inc. Toll Free # 800-996-0070

MATSUBO Powder Processing Equipment

We play an important role in the pulverizing, classifying, and granulating

processes

that hold the key to improving product quality and production efficiency.

There is a questionnaire below.

| Elbow Jet air classifier  |

Turbo-Mill pulverizer  |

is now available for testing and custom processing at AAAmachine, Inc. laboratory in Des Plaines, IL. *** Example ---- Color toner 5 microns (remove fine/coarse at one cut) >>>>>> Please download the EDS (Engineering Data Sheet) to look for test/custom processing service availability. <<< AAAmachine service page >>>

|

<PAC UNIT> |

Electric Vacuum Separator Hair Remover  |

|

| Turbo-Screener round sieve  |

CRACK-U-LATOR granulator  |

|

■ |

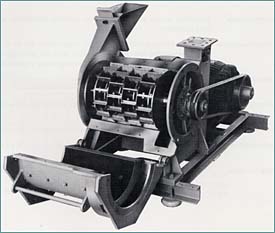

Turbo-Mill [Fine Pulverizer, Mechanical mill] | ||||||||||||||||||||||||||||||||||||||||||

|

The pulverizing mechanism of Turbo-Mill is due to

the percussion caused by high speed revolution of the wings, the

innumerable ultra-violent vortexes which break out behind the revoluted

wings, and the high-frequency-vibrating air caused by these vortexes,

besides the usual pulverizing mechanism of simple impact and shearing. As

the results, any brittle material could be pulverized into the several

microns, and any sticky or elastic materials and heat sensitive materials

could be processed to the satisfactory extent. | ||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||

| FEATURES | |||||||||||||||||||||||||||||||||||||||||||

| ● | Simple and solid design with no internal screens makes maintenance easy and promises trouble-free operation. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Unique method of pulverization can handle a wide variety of materials, both organic and non-organic. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Particle size distribution can be easily adjusted by varying rpm, clearance, and number of rotor stages. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Vortex pulverizing action minimizes contact between feed materials and the machine. Therefore there is little abrasion problem especially in plastics. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Air flow in the Turbo-Mill can carries pulverized particles into cyclone. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Cold or hot air can be used for either low

temperature or high temperature pulverization. Cryogenic pulverization with liquid nitrogen is also possible. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Inspection, maintenance and cleaning can be attained easily by opening the upper casing. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Turbo-Mill is so tight that there might be no problems of dust leaking. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Turbo-Mill is very compact for its pulverizing capacity. | ||||||||||||||||||||||||||||||||||||||||||

| ● | Since pulverization efficiency is high, net power consumption is low. | ||||||||||||||||||||||||||||||||||||||||||

| APPLICATION EXAMPLES | |||||||||||||||||||||||||||||||||||||||||||

| ● | PE, ABS, PVC, PP, PVA, AS, Urea resin, Phenol resin and other synthetic resins | ||||||||||||||||||||||||||||||||||||||||||

| ● | Toner, Powder coating | ||||||||||||||||||||||||||||||||||||||||||

| ● | Limestone, Gypsum, pigment, Asbestos | ||||||||||||||||||||||||||||||||||||||||||

| ● | Flour, Rice, Sugar, Salt, Fish meal, Seaweed, Spices | ||||||||||||||||||||||||||||||||||||||||||

| ● | Paper, Pulp sheet, Rice husks | ||||||||||||||||||||||||||||||||||||||||||

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||

| ● | The hydraulic equipment for opening the upper casing of Turbo-Mill can be supplied at your option. | ||||||||||||||||||||||||||||||||||||||||||

| DIMENSIONS | |||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

■

|

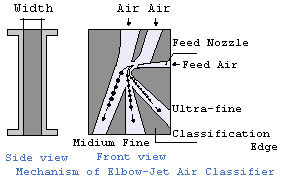

Elbow-Jet Air

Classifier [Simultaneous multi-product air classifier] |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Elbow-Jet is based on the cross-flow classification technology developed by late Prof. Rumf and late Prof. Loschonski in Germany. It is the world's first simultaneous multi-product (more than 2 classification points) classifier. The revolutionary design of the Elbow-Jet offers many outstanding features. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| New

Elbow-jet's new type PURO started Following the CIP feature of LABO type, Capacity is improved for PURO type with removable package construction. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EJ-P-3(PURO) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| STRUCTURE | FLOW SHEET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FEATURES |

APPLICATION

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Simultaneous multiple classification, Coarse and fine separation can be made at the same time. | ● | Toner, Powder coating, Carbon and fine separation can be made at the | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Simple design with no moving parts | ● | Alumina, Silica, Seria | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Easy change of classification points. | ● | Calcium carbonate, Talc, Clay, Bentonite | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Sharp and precise classification | ● | Iron oxide, Ferrite, Metal powder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Easy scaling up to larger equipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Excellent repeatability and stability | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Visualable operating condition - All models have a sight glass to see what is going on inside. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPECIFICATIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■

|

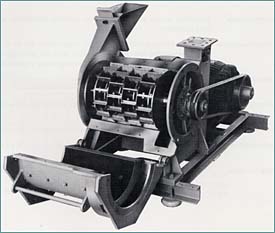

Roll

Granulator [Crack-U-Lator] |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Roll Granulator was developed in 1966 and has been widely used in coffee

industry. Compared with conventional size reduction machines, the Roll

Granulator offers extremely high yields with very little heat generation

and wear. These features are currently put to use in a wide range of fields,

including medicines, chemicals, and foodstuffs. Several hundred Roll Granulators

are currently in operation. Rather than crushing or grinding, the Roll Granulator literally cracks the material into a uniform, narrow range of particle size through a series of patented corrugated rolls. This unique roll surface applies a linear stress in the circumferential direction to the particles being fed into it. Each peak on the roll acts as a fulcrum point to particles bridged across the corrugation of the mating roll. Succeeding sets of rolls are arranged with narrower gap clearance and steeper pitch. As a result, particles smaller than the gap clearance can pass through, while those that are large, are cracked before passing through. Unlike conventional grinders or roller mills that rely on facial compression or friction, the Roll Granulator employs only local stress cracking, thus minimizing the problems of over grinding, abrasion, excess heat-up of roll surface and rapid wear of rolls. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FEATURES | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Since no shear force acts on the feed material,

very few fines are generated. An extremely sharp particle distribution is obtained. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Since no heat is generated at the roll surface, heat-sensitive material can be crushed without difficulty. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Since there is no abrasion, crushing can be performed continuously without readjusting the clearance of a couple of the roll, and operation cost and maintenance cost would be minimized. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Due to no coarse particles larger than the target size, screening process is not necessary. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Agglomerate materials can be ground with full recovery and no damage on the feed materials. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Cleaning and inspection can be performed quickly nad easily. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APPLICATION EXAMPLES | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Medicine : Granules, Granules for tablet making, Recovery of powder from tablets and capsules. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Chemicals : Thermoplastics, Detergents, CMC, Enzymes, Catalysts, Battery filler, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ● | Foodstuffs : Coffee, Peanuts, Spices, Freeze-dried foods | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The above performance figures are for general reference.

Actual performance will very depending on the feed material, size of feed and target product size. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

■

|

Electric Vacuum Separator | |||||||||||||||||||||||||||

|

This revolutionary separator can easily remove the

foreign materials from products by innovatively employing static electric

force. Its excellent separation performance is highly evaluated, and over 500 sets of them have already been put into operation in pharmaceutics, food and chemical industrial field by now. |

|||||||||||||||||||||||||||

| FEATURES | ||||||||||||||||||||||||||||

| ● | Hair can be removed thoroughly. | |||||||||||||||||||||||||||

| ● | Resin fragments can be removed from resin pellets. | |||||||||||||||||||||||||||

| ● | Easily remove the foreign materials or impurities from food products. | |||||||||||||||||||||||||||

| ● | Easily remove the foreign materials or impurities from food products. | |||||||||||||||||||||||||||

| ● | Capable of dealing with large bulk treatment. | |||||||||||||||||||||||||||

| PRINCIPLE | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| APPLICATION EXAMPLES | ||||||||||||||||||||||||||||

| ● | Chemicals : Resin pellets | |||||||||||||||||||||||||||

| ● | Foods : Soft seafood, Wild plants, Tea leafs, Small fishes. | |||||||||||||||||||||||||||

| ● | Foreign materials : Hair, Whisker, Feather, Bag broken scraps, Fishing threads, Straw chips, Wood pieces. | |||||||||||||||||||||||||||

| ● | Separation example : Buckwheat husks from berries, Wood barks from nuts, Tea leaves form stalks | |||||||||||||||||||||||||||

| ● | Pharmaceutics : Tablets, Granular for tablet making, Fine granular, Chinese medicine. | |||||||||||||||||||||||||||

| SPECIFICATIONS | ||||||||||||||||||||||||||||

<< Questionnaire for MATSUBO equipment >> |

||||||||||||||||||||||||||||

This is AAAmachine, Inc. web site.