Mitsumi Flexible Valves: the Solution You Need

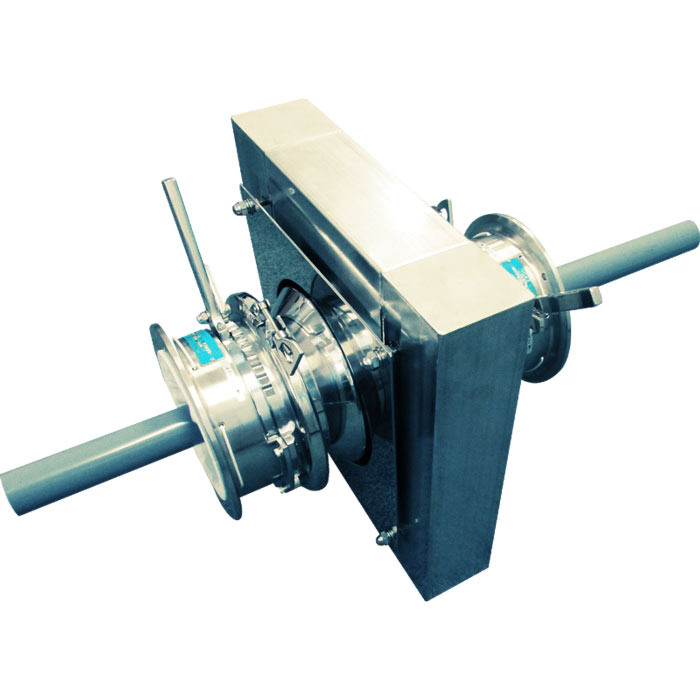

Mitsumi Technical Industry is proud to offer a variety of flexible valves and couplings for use in processing powders and bulk solids.

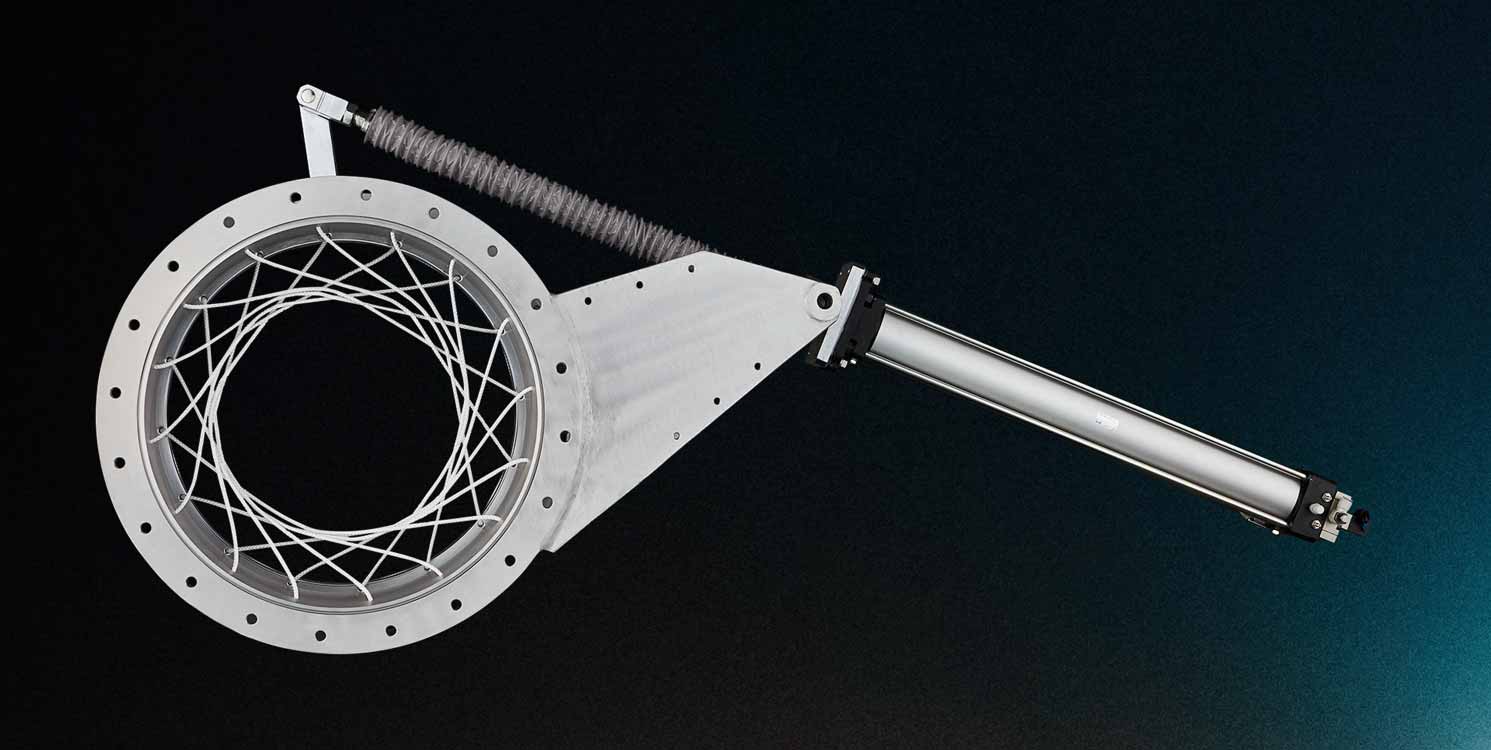

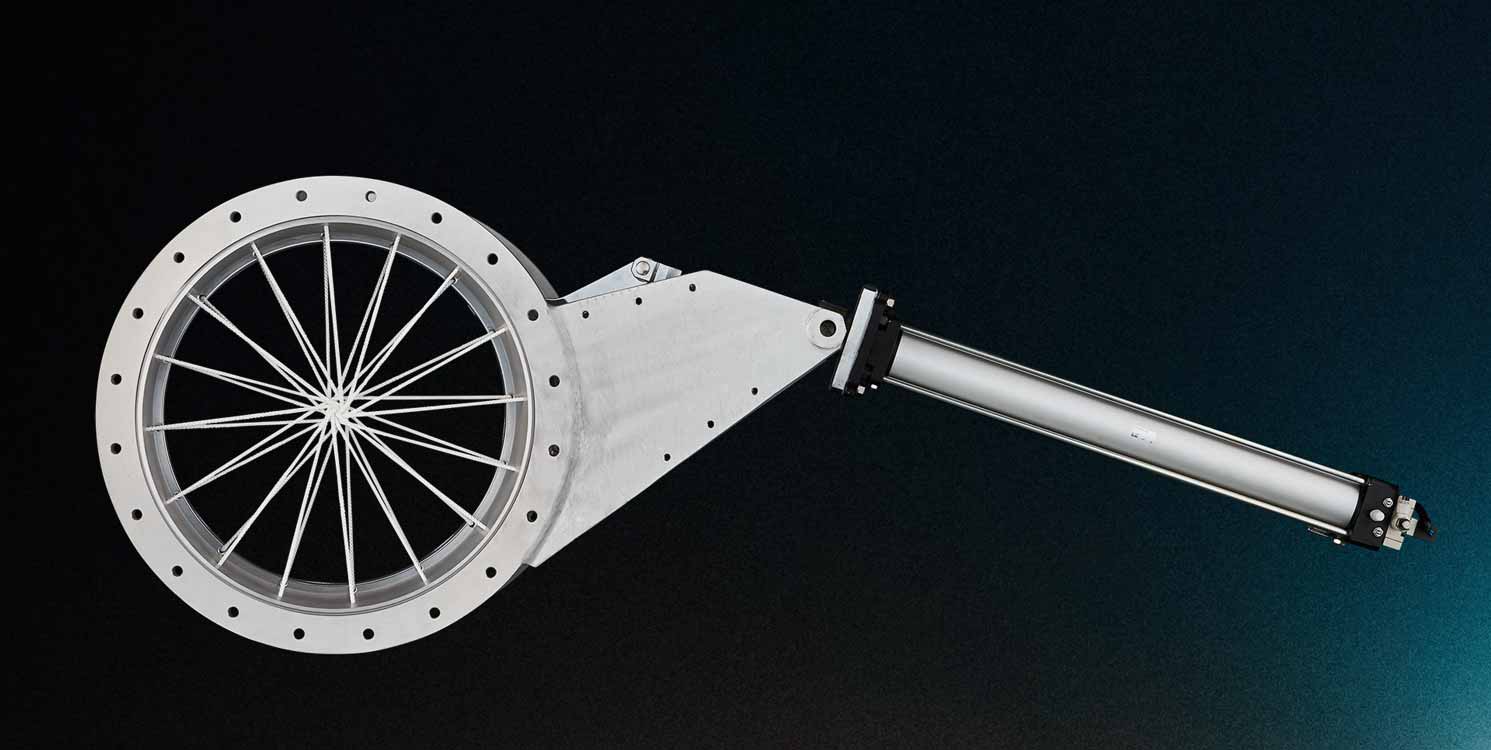

A simple, precision design lies at the heart of all Mitsumi products. Durable metal fittings, high-strength choke ropes, and a range of treated sleeve materials strong enough to withstand even heavy powders give you superior control compared to traditional butterfly and metal valves.

Our valves are the superior choice for processing foodstuffs, pharmaceuticals, chemicals, and other industrial powders.

You can customize your valves using our wide range of fittings and sleeve materials.

Our sanitary iris valves are also well-suited for use as pass through (diaphragm) valves in clean rooms, laboratories, blasting booths, and isolation chambers.

See the Difference with Mitsumi Valves

Mitsumi valves are also easy to operate. A simple 90° 'half-action' turn is all you need to move from sealed, to half feed, to full feed. Valves can be manually operated or fitted with pneumatic air cylinders for automated control.

Read on for a few more reasons we've revolutionized the valve industry, and what we can offer your enterprise:

Heavy-duty Flexibility

Mitsumi valves are engineered around their heavy-duty flexible sleeve materials.

- The action of the valve self-cleans the sleeve, preventing build-up and caking.

- And with no internal components exposed to the material flow there is no risk of flaking.

- Your products stays pure and sanitary.

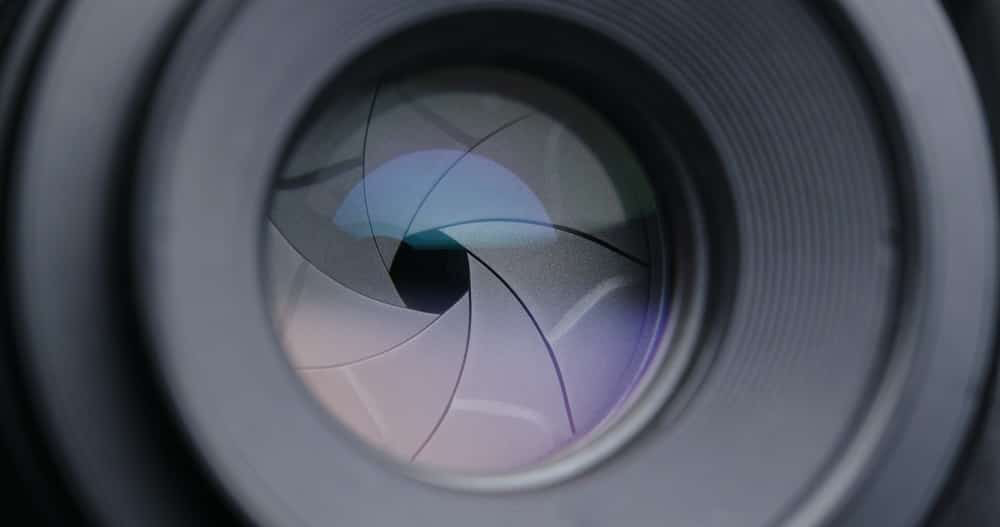

Iris valve: Like a camera shutter or your eye.

Iris valves (called a "choke valve" in some markets) open and close like the shutter of a camera or the iris of your eye. The circular opening creates a cone stream of materials for better flow control, and Mitsumi's iris valve can match metal valves in strength with zero contamination.

Under 2 minutes

When needed, the flexible sleeves can be removed in under two minutes for replacement or cleaning.

We don't waste your time, money, or product.

Natural or Synthetic, all developed to last.

Available in a range of natural and synthetic materials, Mitsumi flexible valves are strong enough to handle heavy and abrasive powders. The treated sleeve material resists wear. High-strength choke ropes seal in even heavy materials normally processed using expensive metal butterfly or slide valves.