Powder Technology Before & After Achive

»» Powder & Green Technology Before & After

2009.11.01 [No.21] Pleats cartridge filter in food grade

|

ACO Pleats cartridge filter (food grade) 1) Place: Dust collector in a food plant 2) What is installed?: Pleats cartridge filter (approved by food sanitation regulation) 3) Before: Standard polyester fiber bag filter was used for food. No food-grade cartridge filter was available. 4) After : 4 times cloth area than bag filter => Dust collector size became 1/3. Up to 150 degreeC temperature air can be used |

|---|

2009.11.01 [No.20] Low price & compact timer control box for air knocker

|

Exen Air knocker (flow aid) timer controller model KSE 1) Place: Ceramics powder plant in Japan 2) What is installed?: Timer control box Model KSE for Air Knocker (AC100-115V/AC200V/DC24V - 3 type, IP65 dust proof) 3) Before: Relay knocker control box was used (no display) 4) After: Timer set (off/knocking time) display is bright and clear. Timer adjustment (0.5 second to 99 hrs - off) is easy by opening the top transparent cover. One control box can handle 2 knockers. Remotely controlled. |

|---|

2009.10.01 [No.19] Air knocker has achieved energy saving

|

Exen Air knocker (flow aid) 1) Place: Dust collector 2) What is installed?: Air knocker RKV30PA 3) Before: In order to discharge very sticky powder from dust collector, higher pressure flow aid (piston vibrator) was used continuously. Very noisy. Vibrator power is limited and continuous vibrating was badly affecting other equipment (ex. making cracks, etc.) * Air consumption * piston vibrator EPV18 -> 17-62 liter/min, ball vibartator CH19 -> 180 liter/min 4) After : No continuous hammering (air knocking) is needed. Less noisy. Less energy consumption (air consumption). In the flow aid devices, air knocker is working at the highest performance in the lowest energy. * Air consumption * air knocker 0.05-0.13 liter/time * 6 times/min. ==> 0.3-0.78 liter/min |

|---|

2009.10.01 [No.18] Wet scrubber has improved maintenance for salt line

|

ACO Wet Scrubber (dust/oil mist/odor remover using water) 1) Place: Food (confectionary) plant in Japan - salt collecting line after drier 2) What is installed?: Wet Scrubber WS-60-P 3) Before: Bag filter was easily clogged because of dewfall and needed to be cleaned every day. 4) After: Salt can be melt/collected in the water at Wet Scrubber. Bag house is no longer needed. Less maintenance. |

|---|

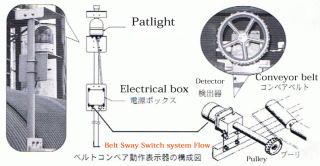

2009.09.01 [No.17] Belt conveyor swaying trouble

|

Matsushima Measure Tech Belt Sway Switch 1) Place: Steel manufacturing plant in Japan 2) What is installed?: Belt conveyor Sway Switch 3) Before: Once extremely long conveyor belt (60-120 m/min speed) was swayed, the belt was damaged. It was difficult to detect the starting of swaying action. Serious damage. 4) After: Belt Sway Switch (activated by belt conveying power, no electric power is needed) can detect the sway start and turn on the Patlight, stop the conveyor, and send the signal to control circuit. |

|---|

2009.09.01 [No.16] Level sensing problem for high temperature liquid

|

Matsushima Measure Tech Pulse radar type FMCW Microwave level meter 1) Place: Steel manufacturing plant in India -- in a blast furnace (1500 degreeC steel melting pot) 2) What is installed?: FMCW microwave level meter (5.8GHz) 3) Before: Melt steel level was monitored by manually, which became products' highest level lower than the full capacity. This degraded the production efficiency. 4) After: FMCW microwave level switch can precisely measure the highest level of steel liquid so that the products can be filled full in the vessel. |

|---|

2009.08.01 [No.15] Recycling Electric Appliance (difficulty in removing fine powder/foam)

|

1) Place: Recycling plant in Japan 2) What is installed?: Jet Separator CFS-400 is installed (300 kg/h - 660 lbs/hr) 3) Before: Dust was remained after pulverizing electric appliances 4) After: Dust and urethance foam rubber can be separated from recyclable coarse |

|---|

2009.08.01 [No.14] 20% energy save Desiccant HVAC (than silicagel) - 40 to 80 degreeC low temp. hot air exhaust can be utilized

|

Mitsubishi Plastics Desiccant HVAC using Zeolite coated honeycomb rotor

1) Place: Fuel battery plant in Japan 2) What is installed?: AQSOA desiccant HVAC is installed - Newly developed Zeolite is coated on the surface of desiccant rotor 3) Before: 40-80 degreeC hot air was not used, just exhausted. 4) After: 40-80 degreeC hot air is now utilized and the humidity is adsoped/controlled separately from temperature. This can reduce running cost 20% -- Great Advantage in Carbon Offset. |

|---|

2009.06.01 [No.13] Recycling PVC floor tile (difficulty in removing fiber)

Before separation |

After separation – PVC |

After separation - Fiber |

|---|---|---|

| ACO Jet Separator (dust remover) 1) Place: Recycling plant in Japan 2) What is installed?: Jet Separator CFS-400 is installed (300 kg/h - 660 lbs/hr) 3) Before: No recycle was possible because fiber can not be separated. 4) After: Polyester fiber can be efficiently removed from pulverized PVC floor tile |

||

2009.05.31 [No.12] Solar power HVAC solution - low temperature hot air exhaust

|

Mitsubishi Plastics Adsorption heat Pump (Maekawa Sesakusho) 1) Place: Health welfare facility in Japan 2) What is installed?: Solar power Adsorption Heat Pump is installed - 70kw (Silica gel is not used to adsorb humidity. Newly developed Zeolite is used.) 3) Before: 60-100 degreeC water was not used. Standard air conditioning was used. 4) After: 60-100 degreeC water is now produced by Solar power and is generating 3-25 degreeC chlled water. This can reduce Carbon Dioxed 64% --- Great Advantage in Carbon Offset. |

|---|

2008.10.31 [No.11] White spot (foreign articles) trouble - PMMA (acrylic) Pellet case

|

ACO Jet Separator CFS-100 (Dust remover) 1) Place: Digital Camera LCD cover plant in Japan 2) What is installed?: Jet Separator (dust remover) CFS-100 is installed just before Injection Molding Machine 3) Before: White spot (plastic dust & metal dust) exists on the cover. Big claim. Reject % was 16%. 4) After : White spot disappears. Reject % beacame 4% (other reasons than white spot). Big improvement. |

|---|

2008.09.30 [No.10] Extruding trouble - Color Toner case

|

Mitsui Mining Kneadex (Open roll continuous kneader) 1) Place: Color Toner manufacturing plant in Japan 2) What is installed?: Kneadex as a replacement of twin screw extruder 3) Before: Wax percentage was limited up to 6%. 4) After : Wax precentage can be increased up to 10%. |

|---|

2008.08.31 [No.09] Transporting trouble in pipe - Powder milk case

|

Exen Air knocker (flow aid) 1) Place: powder milk manufacturing plant in Japan 2) What is installed?: Air knocker (impactor) RKV40PA at piping outside (with U shape attachment) 3) Before: Powder milk sticked and was accumulated on the wall of piping, which makes transporting difficult. 100 mm internal diameter piping. 4) After : Special U-shape attachment with air knocker solved the problem |

|---|

2008.07.31 [No.08] Discharge trouble from hopper - Toner case

|

Exen Air knocker (flow aid)

1) Place: Toner manufacturing plant in Japan 2) What is installed?: Air knocker (impactor) RKV30PA and RKV40PA at hopper outside (with high mount) 3) Before: Toner was difficult to be discharged constantly because of stickiness caused by electro-static charge. Existing flow aid can not be fine adjusted in hammering force. 4) After : Continuous discharge was realized. No chunk-sticking occurs any more. Air Knocker for hopper discharge to prevent from bridging, ratholing, arching, adherence to wall. Exen Air Knocker is a superb bridge breaker -flow aid device, superior to vibrator or air blaster especially for very fine/sticky powder, such as in toner, ceramics, minerals, food, chemical industry. (1) Hammering power can be easily fine-adjusted by simply changing compressed air pressure (2) Applicable to any hopper, cyclone, bag house (3) Compressed air does not touch powder (4) Multiple installation is easy |

|---|

2008.06.30 [No.07] Weighing accuracy - Dosing trouble

|

SARTORIUS Accuracy - Sartorius Ultramicro/Micro Balance is utilized!!

1) Place: Cosmetics plant in Aichi, Japan

2) What is installed?: Zerobalancer ZBS-10micron-20-03 3) Material: Cosmetics (100-150 microns - average, Bulk density: 53 lbs/cf = 0.85g/cc)

4) Target: Dosing 25 mg / bach with accuracy within +- 250 microgram 5) Before: Manual weighing, It took so long to have the right measurement.

6) After : Automatically dosed from Zerobalancer within 30 sec every batch. The accuracy is in the range of 25.00 mg - 25.50 mg for all the products. |

|---|

2008.03.31 [No.06] Cokes plant case - discharge trouble from hopper

|

1) Place: Cokes plant for trash in Aichi, Japan

2) What is installed?: Relay Air knocker RKV100PA (impactor) at hopper outside

2 units / silo discharging spout

(Silo dimension: 20 feet dia. * 13 feet high)

3) Material: Cokes (2-4 inches block)

4) Before : Cokes was difficult to be discharged because of humidity increase due to rain.

5) After : The damp-truck driver can easily load cokes from silo using the installed 2 relay-knockers. The operation panel (OPECON) is installed just in front of the driver position for easy operation The driver operates the knocker for just 1 second for smooth discharge in a short time. |

|---|

2008.0.29 [No.05] Incinerator plant case - discharge trouble from hopper

|

1) Place: Incinerator plant for trash in Kyushu, Japan

2) What is installed?: Relay Air knocker (impactor) at hopper outside (with high mount)

12 units (RVK-100P) high temperature spec. (140 degree C)

3) Before: Ash was difficult to be discharged because of stickiness.

This degraded the boiler performance.

4) After : No sticking/clogging occurs. Boiler performance is improved. |

|---|

2008.01.31 [No.04] Perfect pulverizer for coffee/grain material

|

1) Place: Coffee drink producing plant in Japan

2) What is installed?: "CRACK-U-LATOR"model GRN-6042-4-combination-roll granulator/pulverizer, Roll width 24 inch, Capacity: 1.5-2ton/hr,

3) Before: Other maker' roll granulator was used. 2 problems - generating too much fines below 20mesh (broader particle size distribution). Roller needs to be replaced every 6months or a year.

4) After : 4 combination roll is effectively granulates coffee bean with no heat damage to narrow particle size distribution according to the required spec. (ex. such as 10 mesh to 30 mesh) Very robust machine. No roller change is required for over 10 years. Easy maintenance and easy cleaning. Coffee bean granulating process is drastically changed. This machine works for other grain/food, such as sesami, garlic, nuts, etc. |

|---|

2008.01.31 [No.03] Sugar refining plant case - discharge trouble from hopper

|

1) Place: Sugar refining plant in Chiba, Japan

2) What is installed?: Air knocker (impactor) at hopper outside

24 units (8 knockers/hopper * 4 hoppers)

3) Before: Difficult to be discharged because of sugar producing environment

4) After: No sticking/clogging occurs even in rainy season.Please see the photo. |

|---|

2007.12.31 [No.02] Grain discharge trouble from hopper

|

1) Place: Rice processing factory in Kanagawa, Japan

2) What is installed?: Air knocker (impactor) at hopper outside

3) Before: Peeled/cleaned rice easily stuck to the hopper due to the high humidity and was difficult to be discharged.

4) After: No sticking/clogging occurs and has realized productivity improvement. Stainless Steel body is perfect for food/high humidity area. Without welding, bolting to the plate is enough. It was able to be installed in a short time. Please see the photo. |

|---|

2007.12.31 [No.01] 5 micron pulverized toner can be produced.

1.jpg)   |

|---|

1) Place: Color toner plant in China

2) What is installed?: Coandar type air classifier

3) Before: jet milled polyester nonmagnetic color toner is getting finer to compete with 5 micron chemical toner. The problem was low yield around 50% and it took times to clean the inside of the current forced vortex type air classifier for color change.

4) After : As 3 (fine-middle-coarse) products are collected at the same time using one unit air classifier, coarse cut is combined with pulverizer in a closed circuit. Removed fine can be used for partially adding to raw materials at a low yield (10-30%, depending on the cut point/difficulty of pulverizing). Middle fraction is products. Coandar air classifier does not have any rotor inside, which makes cleaning so easy. Operators should just remove the cover only. Toner process is drastically changed. |

<< Questionnaire for Powder Technology Before & After >>

All fields marked with an asterisk * are required.

Inquiry

Please feel free to contact us from the following