Powder & Green Technology Before & After

|

Good stories related with powder & green technology -- the actual successful stories which AAAmachine, Inc. / AAA Save Energy LLC. believes -- should be informative and useful to many of you in this industry. By using appropriate powder or green technology, many troubles can be solved. Additionally, you should be able to realize the improved capability of your manufacturing process. You may not have immediate problems, but you may find a new technology which could give you a hint, improve your process and/or increase profitability. >>>> Please call 800-996-0070 for further information. |

|---|

2021.10.12 [No.29]

Satake Wet Classifier

|

Satake iClassifier ADVANCED CENTRIFUGAL WET CLASSIFIER |

|---|

【Company A】 Significant Increase in Production Efficiency

[Challenges]

●Amid the rapid increase in demand for their main products, the classification process was a bottleneck in aiming to increase production. Thus the new classification technologies were being sought.

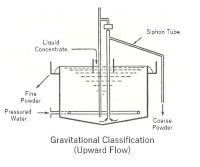

●The raw material of the product was single-micron-size monodisperse particle. The small amount of fine powder and coarse powder in the material were removed by classification. The existing process was carried out in a gravity settling tank.

[Productivity improvement by introducing iClassifier]

●In the existing process, it took 3 days (3d × 8hrs = 24hrs) to classify 1.5 kg of particles per batch; however,

● With the introduction of the iClassifier, the process was shortened to "6 hours". (75% reduction)

【Company B】 Make the impossible possible (Key for homogenization of material form)

[Challenges]

●For the main products, they were required to further reduce the mix rate of coarse particles by the customer.

●In the manufacturing process of the product, the raw material goes through the dry classification to remove coarse particle, but at a very small rate, coarse particles were still tampered.

●They tried to consider removal with various dry classifiers, but could not meet the required quality.

[Realization of high-precision coarse grain removal by introducing iClassifier]

●The introduction of iClassifier and wet-classification has made it possible to remove trace amounts of coarse particles that could not be removed by existing equipment.

●The processing speed is relatively lower than that of dry equipment, thus Satake is continuing to consider equipment scale-up.

Inquiry

Please feel free to contact us from the following