Products ★Powder Bulk Category List

1.Handling equipment, Machinery

▼ Comminution (pulverizing, grinding, milling)AAAmachine toll free #: 800-996-0070

|

|

|---|

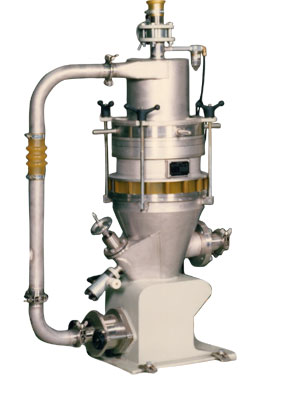

Counter-current Pulverizer

YUTAKA Manufacturing (Aichi, JAPAN)

YUTAKA Manufacturing (Aichi, JAPAN)

Patented in USA, China, Korea, Taiwan, Japan

US Distributor: Nichimo International Inc.

3245 146th Place SE, Ste 220, Bellevue, WA 98007 U.S.A.

|

Counter-current Pulverizer 👉 contact 👉 〔catalog〕Counter-current Pulverizer YTK Series (2,425kb) |

(1) Counter-current (2 rotors rotating in opposite directions) mech anism achieves fine pulverizing of fibrous materials at low

emperature in uniform particle size distribution

(2) Very low operating temperature to protect Vitamin B/C or pulverize oily grain/grain containing sugar

(3) Easy to clean the machine and inspect inside

(4) Particle size can be easily adjusted by turning a handle manually

(5) Rotation speed of the rollers can be adjusted to suit various materials to be pulverized

(6) Replace cryogenic grinding with this counter-current pulverizer

food - Rice, Soy bean, Barley, Spice, Herbs, Green Tea, Carrots, etc.

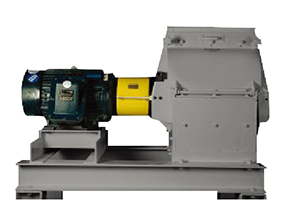

Hammer mill

Prater-Sterling (USA)

👉contact

👉〔catalog〕 (1,647kb)

(1)Original Prater Hammer Mill

(2)Robust

food, plastics, minerals

Crack-U-Lator (Roll Granulator for grain/coffee)

MATSUBO (Japan)

(1) Narrow particle size (less fines, less coarse),

(2) Less heat generation to change the bean/grain characteristics,

(3) Robust - less maintenance, roller replacement? No need.

(4) Nippon Granulator’s original design - 3 stage rollers - best machine in coffee grinding

coffee, bean, grain

Turbo-Mill (mechanical mill)

MATSUBO (Japan)

👉contact

👉〔catalog〕

(1) EASY maintenance - horizontal rotor (user-friendly bearing design)

(2) Narrow particle size

(3) Best performance (yield & energy cost) to produce 7-10 microns average toner

(4) Shape treatment is possible - more circular potato shape (C.I.- circularity index? Good questions. Please call AAAmachine)

(5) Anti-abrasion resistant coating /jacket cooling / cooling rotor are availabl

toner (magnetic/non-magnetic), carbon, graphite, plastics

Super Rotor (vertical mechanical mill)

NISSHIN ENGINEERING (Japan)

👉contact

👉〔catalog〕 (125kb) 👉〔catalog〕 (584kb)

(1) Narrow particle size

(2) Great performance (yield & energy cost) to produce 7-10 microns average toner

(3) Shape treatment is possible - more circular potato shape

(4) Anti-abrasion resistant coating / jacket cooling available

carbon, toner, graphite, plastics

Ultra Rotor (Vertical mechanical mill)

![]()

Altenburger Maschinen JÄCKERING (Germany)

👉contact

👉〔catalog〕(656kb)

(1)Narrow particle size in coarse pulverizing above 10 microns

(2) Explosion proof model available

(3) To be used as pulverizing dryer, too

(4) Big capacity pulverizer is available

grain, cosmetics, carbon, plastics

Super Jet Mill (jet mill)

NISSHIN ENGINEERING (Japan)

👉 contact

👉〔catalog〕 SUPER JET MILL/SJ(113kb) 👉〔catalog〕 SUPER JET MILL 4page(6,408kb)

(1)Narrow particle size

(2) Great yield to produce 4-7 microns average non-magnetic toner

(3) More circular shape than counter type jet mill

(4) Easy to be combined with Coanda type air classifier for fire removal

resin, ceramics

IDS-2 (ultrasonic impact jet mill)

NPK-Nippon Pneumatic Mfg. (Japan)

👉 contact

👉PDF brochure DOWNLOAD

Not available

(1)All the particles hit impact plate.

(2) Extremely high pulverizing efficiency because of impacting

(3) Very hard material can be pulverized by this jet mill

(4) No moving part, easy maintenance/cleaning

(5) Great performance (yield & energy cost) to produce narrow/sharp PSD

(6) Production scale model is widely used in industries (toner, powder coating, etc.)

toner, powder coating, resin, ceramics

CPY+UFS (Ultrasonic impact jet mill)

NPK-Nippon Pneumatic Mfg. (Japan)

👉 contact 👉〔catalog〕(329kb)

(1)Great performance (yield & energy cost) to produce 4-10 microns average toner

(2) No moving part

(3) Built-in static air classifier (closed circuit) gives best performance

(4) Production scale model is widely used in industries (toner, powder coating, etc.)

toner, powder coating, resin

Jet-O-mizer (jet mill)

Fluid Energy (USA)

👉 contact

👉〔catalog〕 (347kb)

(1)Vertically oriented jet mill with tangential grinding nozzles located at the bottom and static classification occurring at the top. Capable of grinding dry powders to 1-50 micron averages, this vertical jet mill produces a narrow particle size distribution, consumes less energy and is easy to feed with a wide variety of materials.

(2) Sanitary designs for access to gas and product contact areas

(3) No blow back, easy feed operation

(4) Replaceable grinding nozzles and liners--> Specialized liners for abrasive applications

(5) Combined operations - grinding/blending, grinding/coating

(6) Largest range of throughput with models for one gram batches (or rates up to 10,000 lbs. per hour)

resin, plastic, ceramics

Fine Mill (dry type media agitating mill)

NIPPON COKE & ENGINEERING (JAPAN)

👉 contact

👉PDF brochure DOWNLOAD

Not available

(1 Dry-type media agitation grinding machine with classification function

(2) Capacity: 2kg/h - 100kg/h

(3) Motor HP: 22KW - 30KW,

(4) Easy to control grain size, and sharp grinding

(5) Sub-micron dry grinding using media

Various glass, alumina, silicon nitride, ceramics, silica, and inorganic materials

SC(QC)/MSC mill (media agitating mill)

NIPPON COKE & ENGINEERING (JAPAN)

👉 contact

👉〔catalog〕 SC_Mill-Mitsui_Mining_4page

👉〔catalog〕 MSC_Mill-Mitsui_Mining_2page

👉〔catalog〕Calcium_Carbonate_Grinding_Process

(1)Sub-micron and nano-meter size wet grinding/dispersing using media

(2) Union Process (http://www.unionprocess.com) also sells QC-mill with Attritor

(3) Best matching with Attritor

(4) MSC mill- Media size from 15 microns to 200 microns in diameter. No screen is used - no clogging on screen. (SC mill - Media size 200 microns or coarser. Media separator is used)

calcium Carbonate, talc, minerals, ceramics, paper industries

Nano Jet Pul (wet jet mill, media-less wet disperser)

JOKOH Co., Ltd. (Japan)

👉 contact

👉〔catalog〕 (130kb)

Model: JN-20

(1)Media-less wet grinding/dispersing ---> No media is used, less contamination

(2) 4 objectives by one unit - disintegration, grinding, mixing, emulsification/homogenizing

(3) High pressure up to 250 MPa by built-in plunger pump

(4) High viscosity (up to 20,000cP) sample can be fed

(5) From 4 ml/batch (JN10) to 60 liter /h (JN1000) production model is available.

Carbon nano-tube (CNT), Barium Titanate, Cellulose, Carbon black, Nickel, cosmetics, pharmaceuticals, foods, cluster water, etc.

Inquiry

Please feel free to contact us from the following