Kawata Superfloater mixers use vibration and agitation mechanisms to improve even further on Kawata’s Supermixer technology. See energy savings up to 70 percent over your current mixer. Superfloater mixers excel at mixing and wetting fillers, stabilizers, lubricants, and pigments.

Kawata mixers are smaller, faster, and more efficient than other mixers on the market. Superfloater mixers can process challenging materials without requiring additional mixing or processing equipment.

Do away with mixing bowl cleaning thanks to the Superfloater’s sanitary mixing bag system. Work with Kawata engineers to customize mixers to your exact specifications.

World's

1 st

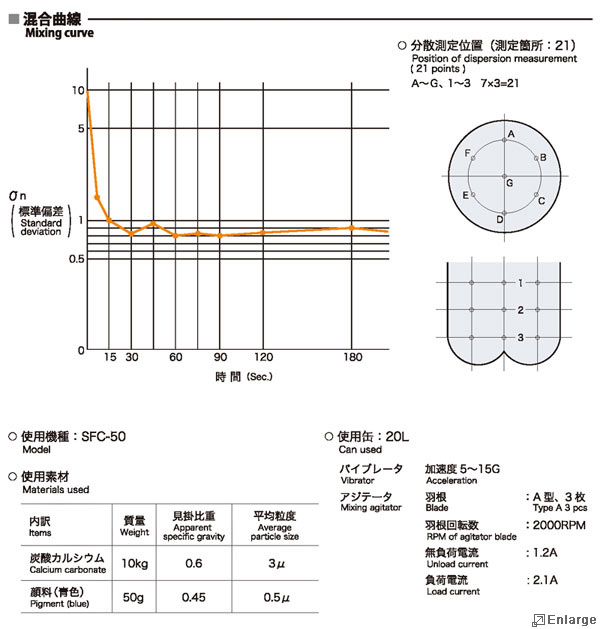

The Kawata Superfloater combines powerful industrial technologies. It is fast, efficient, and produces high-purity materials with 100% yield. The shape of the mixing tank combined with vibration and agitation systems makes highly-precise batch mixing possible. The Superfloater is an ideal mixing system for R&D, mixing exams, and high-value small-batch production.

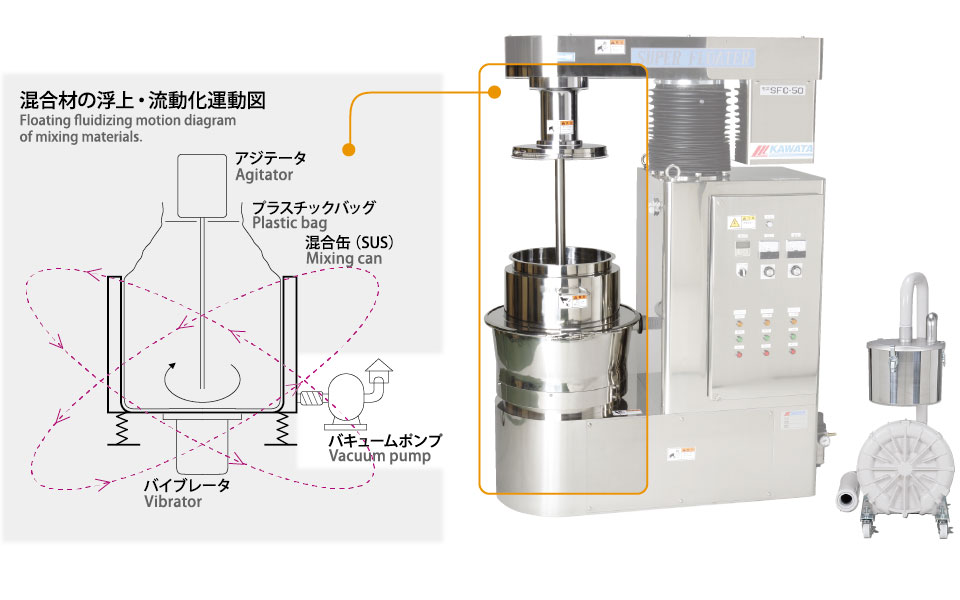

A vibration unit is mounted to the bottom of the Superfloater’s mixing tank, which vibrates at high speed to prevent material from adhering to the tank wall. Meanwhile, an agitator unit uniformly mixes material in the tank. Together, these systems improve material dispersion and provide superior mix yield.

Superfloater mixing tanks have a replaceable sanitary liner that prevents mixing materials from ever coming in contact with the mixing tank. And since the material is completely enclosed in the plastic bag, you can easily transport it to and from the Superfloater unit.

Or schedule an appointment at our Chicago,

demo facility to see a Kawata Superfloater mixer in action.

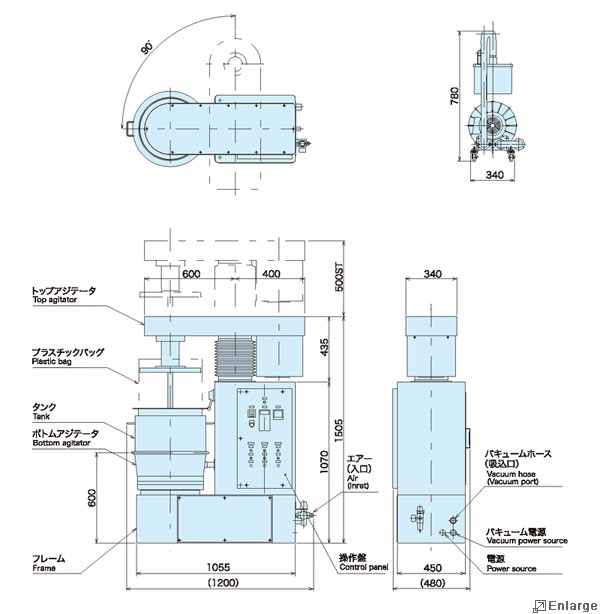

| SuperFloater Specifications | |

|---|---|

| Model | SFC-50 |

| Bottom Agitator | 3 Phase, 200V 0.4kW, Inverter Type |

| Top Agitator | 3 Phase, 200V 1.5kW, Inverter Type |

| Vacuum Pump | 3 Phase, 200V 1.3/1.9kW (50/60Hz) |

| Mixing Vessel (Can) | Selection 10, 20, 50 Standard |

| Tank Material | SUS304 Japanese Standard Stainless Steel |

| Power Supply | 3 Phase, 3.2/3.8kW, 30AT (50/60Hz) |

| Air Capacity | 60L/min (ANR), 0.69MPa |

| Machine Weight | Body: 400kg, Vacuum Pump: 45kg |

| Installation Space | 1 meter x 1 meter |