The Kawata Nanopersion Mixer is specially designed for the grinding and mixing of ultrafine particles (nanoparticle scale). Kawata engineers have designed a mixing system that reaches 16,000 rpm to disperse, shear, and mix particles at industry-leading speed and efficiency.

Nanopersion Mixers produce high levels of surface modification in a much shorter time than traditional mixers. The Nanopersion is ideal for ultrafine mixing needs where wet mixing isn’t an option.

| Nanopersion Mixers (HDPE-100 / 300) | Nanopersion Piccolo (HDPE-2) |

|---|---|

| High-speed Mixers for Ultrafine Mixing | Desktop Ultrafine Lab Mixer |

The Kawata Nanopersion Mixer is the ideal mixing solution when you need ultrafine shearing and mixing with no agglomeration. It boasts a powerful yet simple design that is easy to disassemble and clean.

Its unique design allows for the mixing blade to rotate at up to 16,000 rpm, producing a blade tip speed of 100 m/s. That action can rapidly disperse, shear, and mix ultrafine particles that traditional industrial and lab mixers cannot replicate.

Nanopersion Mixers are ideally suited for cosmetics, particularly mixing foundation compounds and foodstuff mixing where low agglomeration is critical. They are also well-suited to producing powdered silver, alumina, and silica.

Kawata’s Nanopersion Piccolo Mixer is a desktop laboratory model utilizing the same revolutionary nanoparticle mixing system as the full-scale Nanopersion HDPE Mixer. Just like its full-size counterpart, the Piccolo is capable of blade rotations up to 16,000 rpm and blade tip speeds of 100 m/s. The smaller-scale Piccolo features a cooling jacket and operates at 100 V.

The Nanopersion Piccolo is also designed for easy disassembly and cleaning. It is suitable for small batch test runs and experimentation.

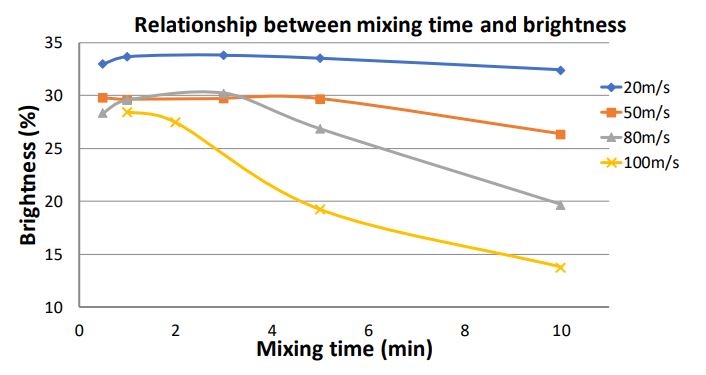

The more uniformly the black nanoparticles of acetylene black are dispersed on the surfaces of the white calcium carbonate particles, the more the brightness decreases (the color becomes black), and this serves as a criterion for determining the degree of dispersion and mixing.

Graph 1 shows the results of mixing and dispersion of calcium carbonate microparticles and acetylene black nanoparticles at different blade tip rotational speeds.

It was found that as the tip speed increases, the brightness of the mixture tends to decrease rapidly, indicating that dispersion of the acetylene black nanoparticles has progressed.

Photograph 2 shows SEM photographs of powders at different mixing speeds. When the mixing time was 10 min, large agglomerates of acetylene black nanoparticles were observed, even at a tip speed of 80 m/s.

However, when the tip speed was 100 m/s, the presence of large agglomerates was not observed, making it possible to confirm that the nanoparticles were almost uniformly dispersed on the surfaces of the large calcium carbonate particles.