Products Index

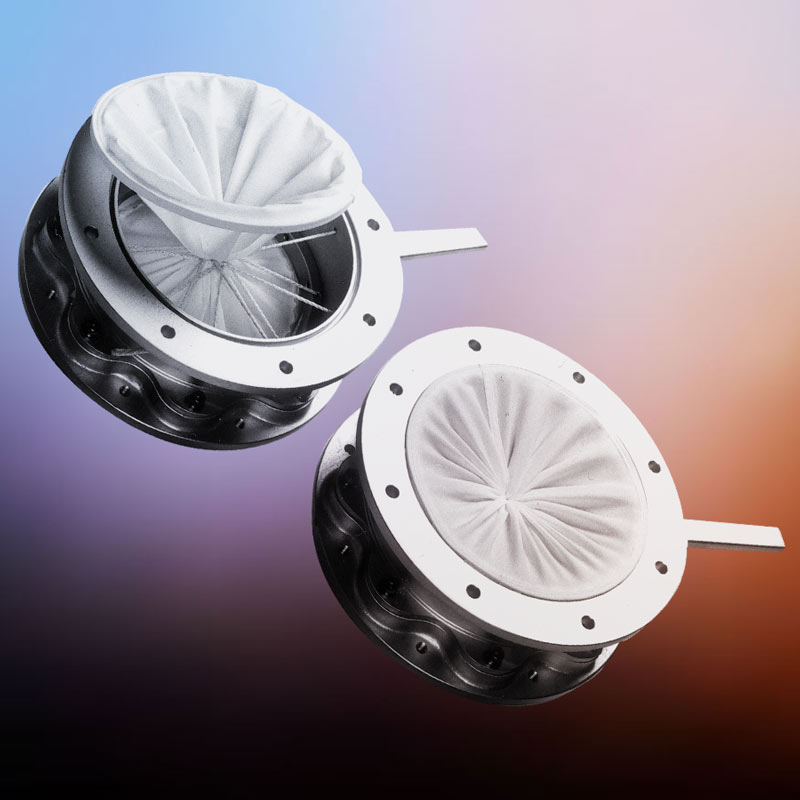

Iris Valves (Choke Valves)

Game changing Iris valves:

Tighter seals that hold finer and heavier powders than any Iris valve you know along with no flaked metal in your output?

Flexible, sanitary design that is strong enough to surpass metal valve performance?

Learn more about why we’re hands-down the best choice for your business.

Efficient sealing and flow throttling with ‘half-action’ 90 degree manual handle or actuator lessens worker burden and wear.

Suitable for processing a wide range of bulk solids, from heavy particles like metals and ceramic to fine powders. Including sanitary applications. Learn more here:

Iris Valve

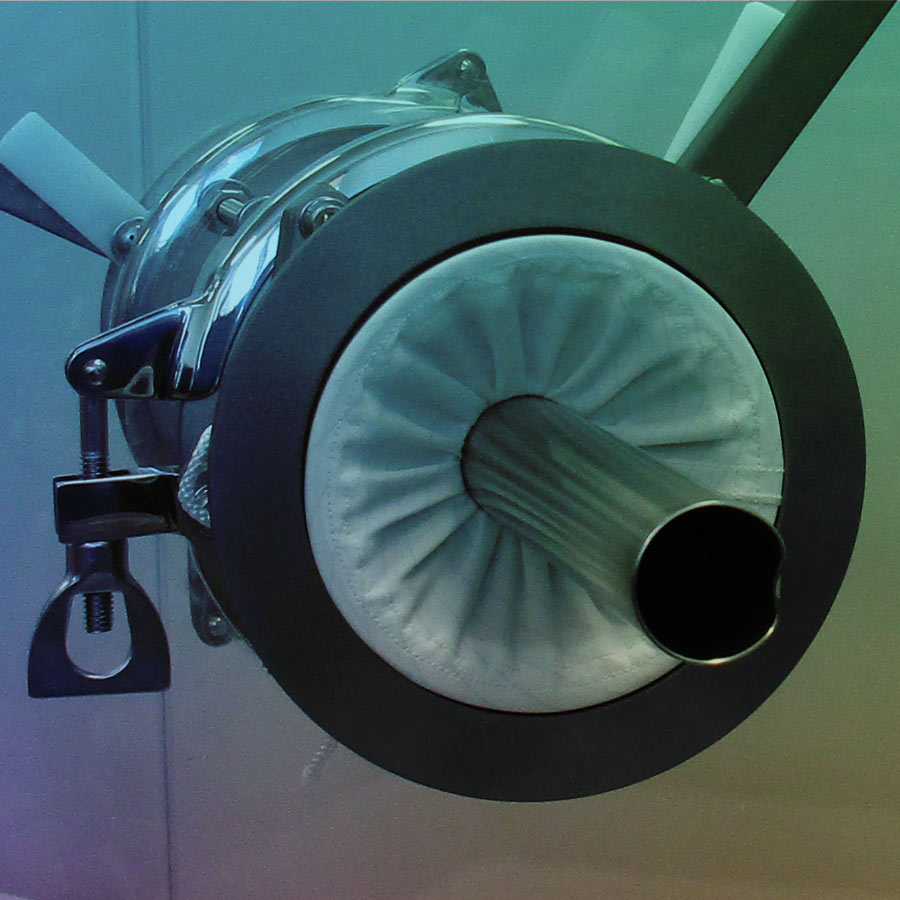

Wall Pass Through Valves

Iris valves for clean rooms; why Mitsumi is the clear choice.

Flexible diaphragm sleeve and cords can accommodate a wide range of tube and pipes. Easy-to-use half-action handles makes running new conduits a snap.

Adaptable to a wide range of isolation facilities, including clean rooms, laboratories, blasting booths, and others, Learn why we’re the choice of clean room environments here.

Wall Pass Through Valve

Diverter Valves

Self-cleaning means better end results, period.

Unique flexible design separates all moving parts from your product to eliminate clogging and cross-contamination.

Appropriate for agricultural, chemical, food, mineral processing, plastics, textiles, and other industries.

Learn more about why Mitsumi’s Diverter valves are second to none here:

Diverter ValvesCustomizable Design, Solutions that fit your exact needs

- Mitsumi valves can be adapted to a wide range of industrial and R&D environments.Mitsumi manufactures valve fittings as small as 3.5” (80A) up to 25” (600A) in diameter.

- All valves come in both manual and automatic operation models, including compressed air cylinder and rotary actuator models.

- Many different types of sleeving are available, and sleeves are replaceable in under two minutes so you can easily process materials with varying properties with little fuss, and excellent results.

- Sleeve materials can be manufactured with a variety of different treatments, including for anti-static or anti-clogging action.

- And that’s the just the technical specs.

-

What that means for your business and staff is higher quality output, purer products,

shorter cleaning time, quick switch up time for more efficient routines and a smarter smoother process flow.