Diverter Valve

Self Cleaning and More Effective Particle Flows: Mitsumi Diverter Valves

The point of a diverter valve is regulate the flow output of your powder in a sanitary, uncontaminated environment. So why aren’t all diverter valves designed to make sure the wrong materials aren’t stuck in piping left to contaminate the output?

We solved that problem.

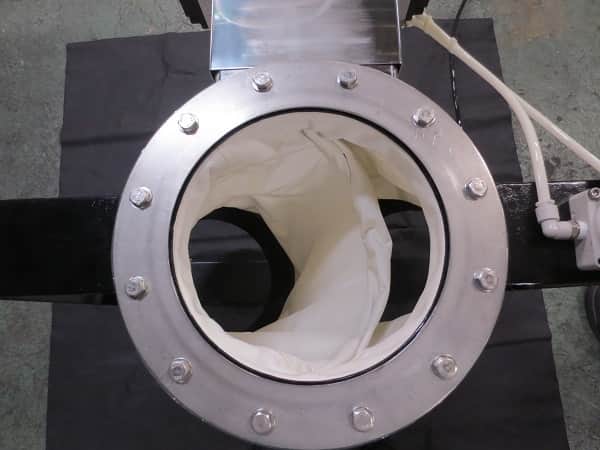

Mitsumi Diverter Valves are designed for processing a wide range of bulk solids, from heavy particles to fine powders. They are especially suitable for sanitary applications and are constructed to ensure the quality and purity of your processed materials. Due to the flexible valve design the valve sleeves self-clean as the diverter moves to redirect material flow.

The diverter swing arm is completely external to the sleeve, so the sleeve is the only surface that comes in contact with your materials. Both manual and automated control models are available.

Ideal for controlling flow discharge at hoppers, IBCs, or processing equipment.

Key Features

General Specifications

A, AH, SS = Aluminum, Aluminum Hardened, Stainless Steel.

| Component | A ModelIris Valve |

AH ModelIris Valve |

SS ModelIris Valve |

|---|---|---|---|

| Casing | Aluminum alloy (AC7A) with surface hardening | Aluminum alloy (AC7A) with PTFE hardening | Stainless Steel (SUS304) |

| Bore Size | 4.5” (100A) – 12.5” (300A) | ||

| Semi-Circular Stems | SUS304(JIS) | ||

| Handle (Manual) | Polyoxymethylene (POM) | ||

| Arm (Automatic) | SS400(JIS) | SUS304(JIS) | |

| Automatic Type | Rotary Actuator with Air Cylinder | ||

| Sleeve | Cloth: PTFE, cotton, silk Synthetics: nylon, polyester, polyethylene, rubbers, PVC, Hypalon, Viton, etc. Other: natural rubber, aluminum leaf laminated sheets, etc. | ||

Sleeve Treatments

- Anti-static polyester with external silicone coating

- Nylon cloth with external silicone coating

- Nylon cloth with external urethane coating

- Nylon cloth with external Acrylic coating

Models

Mitsumi diverter valves are available in either pneumatically-controlled or manually operated models.

Automatic Type