How It Works

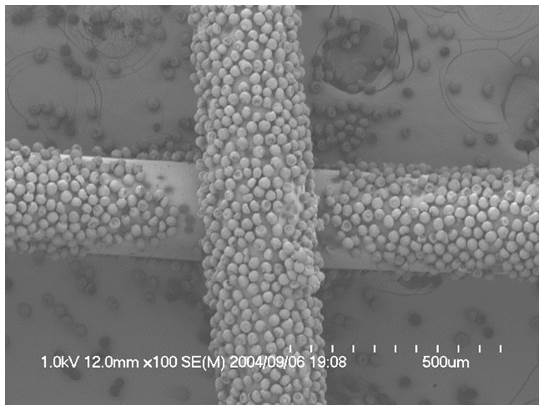

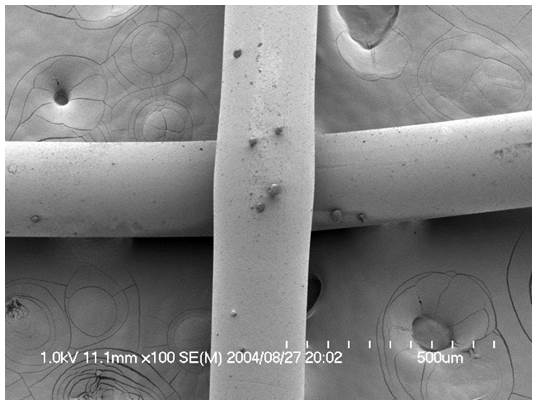

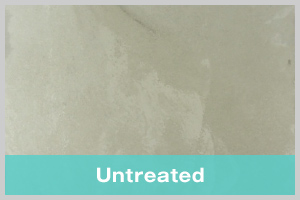

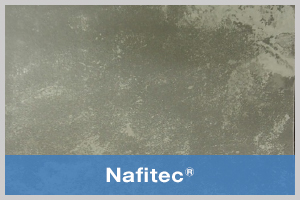

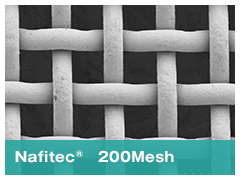

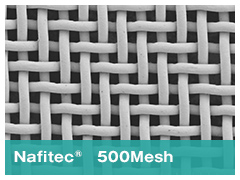

Nafitec® is NBC Meshtec's proprietary nanoparticle treatment process. NBC Meshtec developed Nafitec® to overcome the limitations of conventional nanocoating treatments. Quality made in Japan.

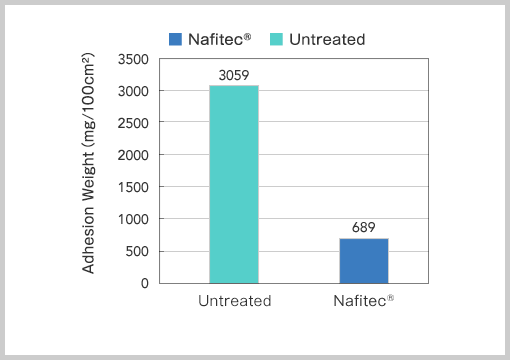

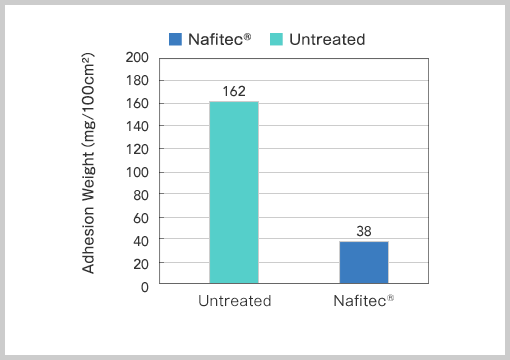

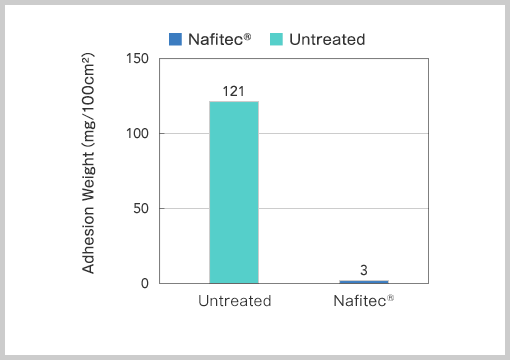

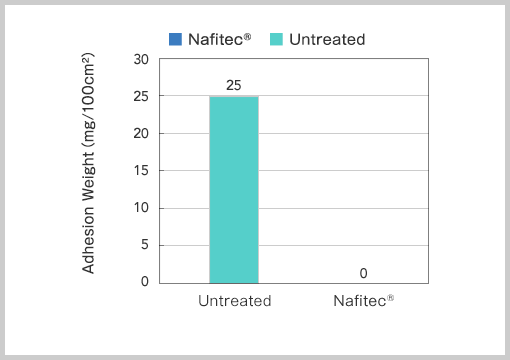

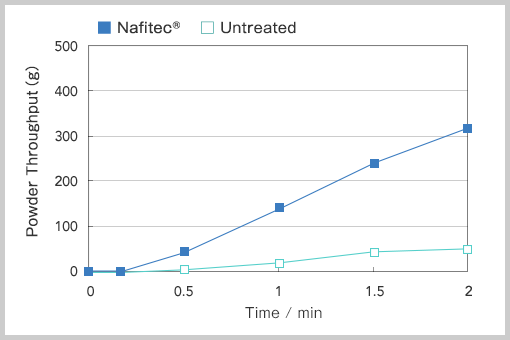

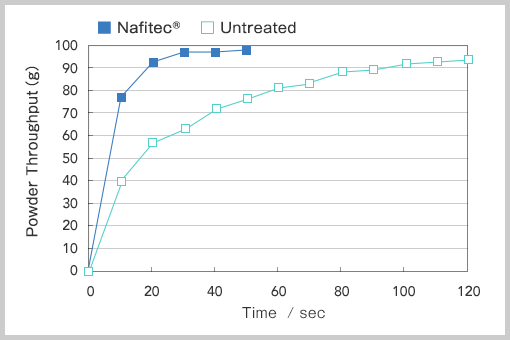

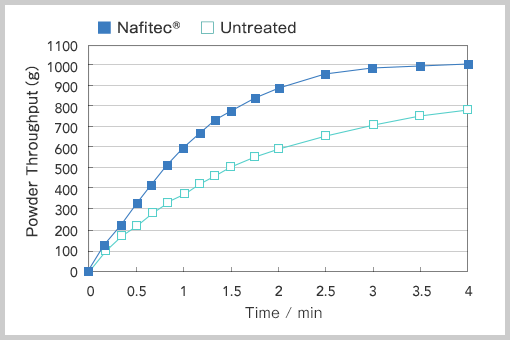

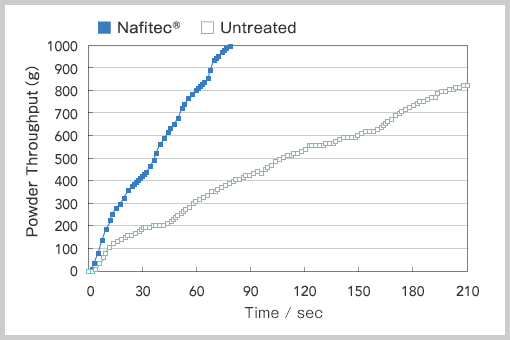

The Nafitec® process was developed to improve the performance of functional inorganic nanoparticles affixed to a broad range of material products. In particular, it has been found to greatly improve industrial particle classification when applied to sieve screens. The vastly improved deblinding ability of Nafitec®-treated screens increases throughput rates and boosts efficiency.