NBC Meshtec Solutions

NBC Meshtec produces Nafitec®-treated sieve and filtration screens to fit a wide variety of industrial applications. Nafitec screens are the superior choice, whether you need to:

- Achieve higher sieve throughputs

- Classify charged, ultra-fine, or other delicate powder materials

- Remove complex impurities or pathogens

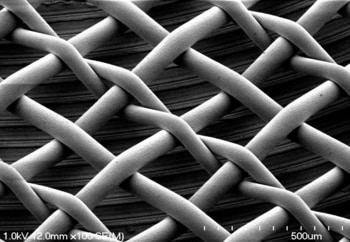

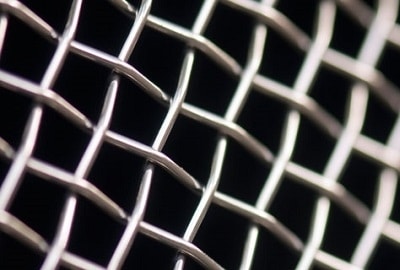

Sieve Screens

We produce sieve screens from multiple different materials, treated and configured to a wide variety of industrial specifications. Our screens are available both conventional and with Nafitec® treatment, tell us what you need and we can get you a quote today.

Nafitec® sieve mesh specifications

You need mesh for a specific powder production, we have the mesh you need.

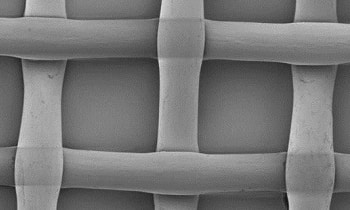

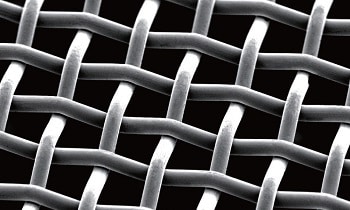

Z type

Particle size:Powders of tens of micrometers or more

S type

Particle size: Powders of tens of micrometers

F type

Particle size: Powder with particle size of 10 micrometers or less

Note:

The particle size is an approximate value. The effect depends on the material and shape of the particles in addition to the particle size. Please contact us to customize a solution for your specific needs.

Materials

Compatible with all materials used for metal, nylon, polyester, and other materials for sieve mesh.