GF Corporation Micro Mist Spray Dryers for Laboratory or Production Scale

Create the finest scale powder in production without using a pulverizer!

Save time, space, energy, and money with the GF Corporation Micro Mist Spray Dryer!

GF Corporation Spray Dryers have revolutionized the field of spray drying with the Micro Mist Spray Dryer and its four-fluid nozzle.

The four-fluid nozzle atomizes liquid droplets into a fine mist, which is then dried to create a more refined product in less time and fewer steps.

GF Corporation offers two categories of Spray Dryers to meet your requirements,

and all feature our innovative four-fluid nozzle system for superior spray drying.

Read More About Our Different Products

GF Corporation's Four-Fluid Nozzle System

Both the Micro Mist Spray Dryers for experimentation and the larger scale models for production feature the four-fluid nozzles which offer a capacity for highly accelerated production that is matched by no other spray dryer.

Both the Micro Mist Spray Dryers for experimentation and the larger scale models for production feature the four-fluid nozzles which offer a capacity for highly accelerated production that is matched by no other spray dryer.

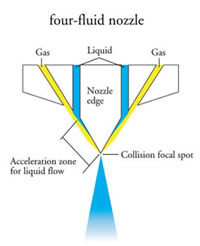

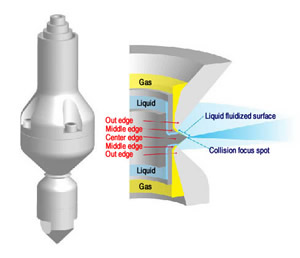

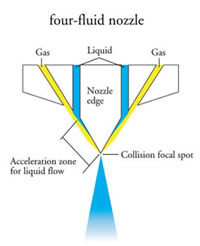

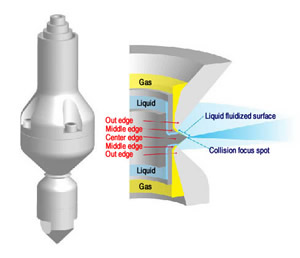

Technology behind the MMSD's four-fluid nozzle

- Mixed flow of pressurized air and liquid is accelerated toward a central edge

- The mixed flow of liquid and gas from both sides of nozzle collide at the nozzle tip

- This high speed collision of mixed flows creates a shock wave

- The shock wave atomizes the liquid into the finest mist

- Hot air dries the atomized droplets that now have more exposed surface area, allowing for faster more effective drying

Four-Fluid Nozzle Functions

- Produce a spray of single micron droplets (5-15 microns) in a uniform mist from small scale (experimentation) to large capacity (production)

- Control the droplet median diameter by changing gas-liquid ratio

- Create an incredibly uniform powder with very narrow particle size distribution

- Spray high viscous liquid, up to 5000cp; inferior spray dryers (2-fluid nozzle and rotary atomizers) cannot handle such high viscosity and require more preparation before spraying

- Continuously spray high viscous liquid without interruption thanks to external mixing which prevents nozzle clogging

- Control spraying capacity by simply adjusting the edge length

- Mix two different liquids to create new kinds of products using only one system and one step

Advantages of GF Corporation Spray Drying Equipment

Create Fine Spherical Powder of 5-15 Microns

- Improve dispersibility of materials to be mixed

- Improve uniform mixing and kneading ability

- Improve tablet filling efficiency of agglomerated fine powder into various vessels through smaller particle size (Pharmaceuticals)

- Improve solubility of a material though the drying process (Pharmaceuticals)

- Improve extensibility (Cosmetics Industry)

- Develop lung specific drug delivery systems that could not be produced with larger particles (Pharmecueticals)

Transform Liquid Material into Manageable Dry Powder

- Improve yield by removing moisture and stickiness to minimize the amount of undried or agglomerated particles

- Create powder with heat solubility and deliquescence that will not get dried easily

- Transform highly viscous liquid into powder (unachievable using other spray drying methods)

Dry Materials at a Low Temperature

- Attain powder form without heat denaturation

- Preserve original flavor though use of lower temperatures (Food Production Industry)

Experience New Levels of Quality with our more Refined and Uniform Powder

- Maintain quality and stability at the molding process through the evenness of the particle diameter

- Create dried powder for use as slurry primary particle (Ceramics)

- Develop better drug release products for digestive organ retention (Pharmaceuticals)

- Develop new functional material by spray drying slurry containing submicron and/or complex particles

- Create material for masking or coating

Download PDF Brochures of the GF Corporation Micro Mist Spray Dryers

Learn More About Our Products

Both the Micro Mist Spray Dryers for experimentation and the larger scale models for production feature the four-fluid nozzles which offer a capacity for highly accelerated production that is matched by no other spray dryer.

Both the Micro Mist Spray Dryers for experimentation and the larger scale models for production feature the four-fluid nozzles which offer a capacity for highly accelerated production that is matched by no other spray dryer.