Cryogenic Grinding Service

OGL has refined their cryo grinding process over the past 30 years. Now, with a new generation of industrial milling and cryogenic technology we are offering our services to the US market.

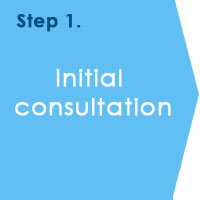

The OGL Toll Grinding Workflow:

Toll grinding with OGL is a straightforward process, even when you need to grind new or exotic materials. Here is what you can expect after first contacting OGL:

1.

You have an initial consultation with OGL cryo grinding engineers to set your requirements, such as specific thermal conditions and target particle sizes.

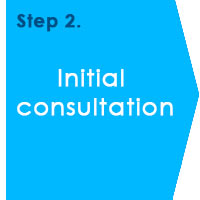

2.

OGL conducts one or more small batch test grinds to calibrate instruments and machinery.

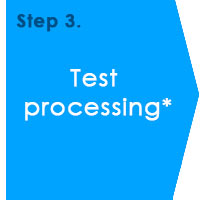

*Test material criteria: Pellets, powder, etc; 0.2” (5mm) diameter units or smaller; 1-225lb (1-100kg) batches.

*Food test criteria: Less than 100,000/g general viable bacteria count; E coli negative after 10x serial dilution.

3.

You review the results of test batch grinding.

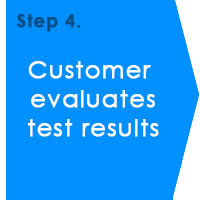

4.

Once scope is confirmed, OGL prepares a final quote and you discuss details for full production grinding with OGL engineers.

5.

OGL processes your materials to your exact specifications

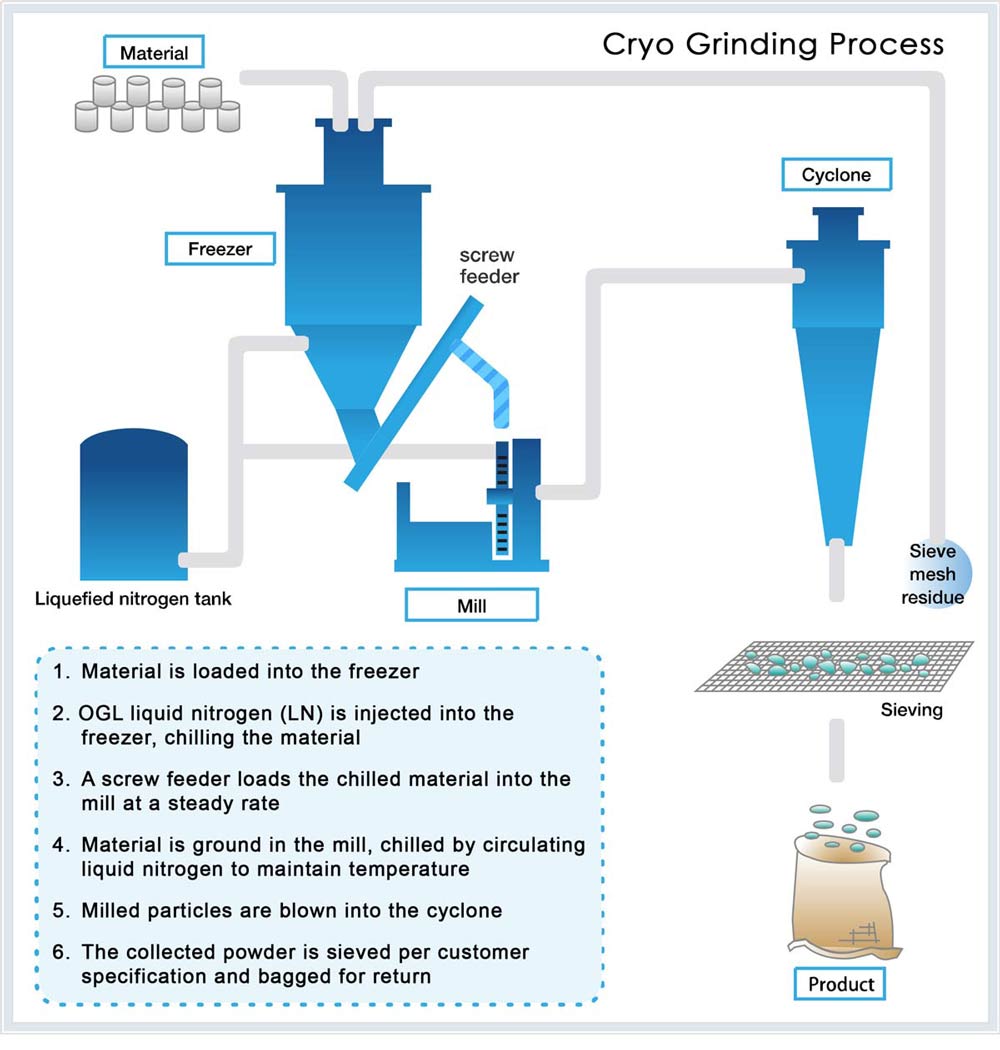

Cryogenic Grinding Process

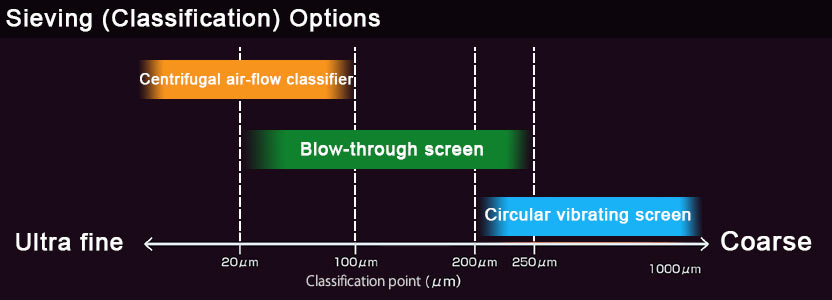

Sieving (Classification) Options

After grinding, material can be classified using a combination of screens and blowers. This process is highly customizable, which allows OGL to process raw materials at a wide range of specifications, including target particle size and particle distribution range.

Residue buildup on the classifiers is also collected and fed back into the freezer for reprocessing, reducing your total waste volume.

Centrifugal air-flow classifier

A combination of forces produced by rotors (centrifugal) and air flow (centripetal) separate coarse from fine particles. Adjusting rotor speed controls the classification point.

Blow-through screen

A reverse blown air stream cuts collected powder and prevents clogging.

Circular vibrating screen

An unbalanced motor vibrates the transport screen on x, y, and z axes for even and efficient classification of larger particles.

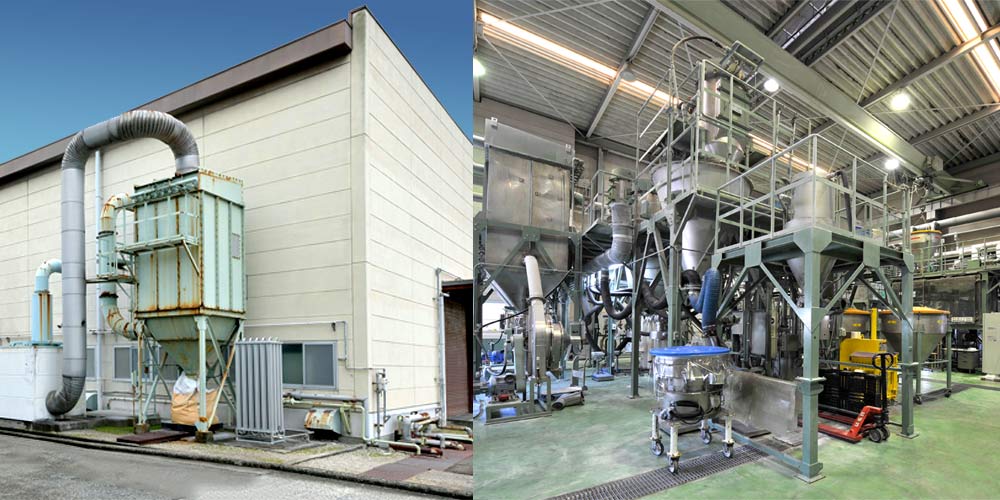

OGL Polymer Grinding Centers

Our polymer grinding facilities are ISO 9001 certified. OGL polymer cryo grinding centers are staffed by experienced teams of industrial engineers and analysts. These centers house several specialized sets of processing equipment and instrumentation to handle any combination of polymer grinding, drying, classification, and mixing needs.

Polymer Grinding Specifications

| Material | Particle size (Distribution) examples | |

| Polypropylene | D10=31μm, D50=81μm, D90=158μm | |

| Polyester | D10=12μm, D50=26μm, D90=52μm | 90% below 106 microns (140 mesh) |

| Polyamide | D10=8μm, D50=25μm, D90=56μm | |

| Polyacetal | D10=10μm, D50=38μm, D90=87μm | |

| Polyurethane | D10=31μm, D50=77μm, D90=185μm | 90 % below 500 microns (35 mesh) |

| Elastomer | D10=73μm, D50=207m, D90=460μm | |

| PolyPhenyleneSulfide (PPS) | D10=14μm, D50=28μm, D90=51μm | |

| PolyEtherSulphone(PES) | D10=11μm, D50=22μm, D90=38μm | |

| Fluorocarbon polymers | D10=8μm, D50=31μm, D90=70μm | |

- Electrostatic powder coating

- Fluid-dip coating

- Coating agents

- Plastic additives

- Composite materials

- Hot-melt adhesives

- Recycling

- Improved dispersibillity

- Industrial cleaning agents

- etc.

OGL Food Grinding Centers

Our dedicated food grinding facilities are ISO 9001, HACCP, and FSSC 22000 certified to ensure the highest levels of food safety (FSSC 22000 includes ISO 22000 and ISO/TS 22002-1/4). They house a variety of classification and drying equipment configured to produce the highest possible quality finished products.

Food Grinding Specifications

| Material | Particle size (Distribution) examples | Features | |

| Sesame seeds | 180- 300μm | 85% below 250 microns (60 mesh) | Taste, flavor and smooth texture |

| Coffee beans | 5 - 45μm | 99% below 38 microns (400mesh) | |

| Tea leaves | 95% below 45 microns (325 mesh) | ||

| Soy beans | 99% below 26 microns (500 mesh) | ||

| Pork bones & chicken bones | 60- 100μm | Very smooth texture, flavor and taste | |

| Raisins | 15- 60μm | Sharp acidity | |

| Almond | 5- 40μm | Good flavor and texture | |

Toll Drying

OGL is also happy to process toll drying orders for any pelletized material. Our drying processes are optimized to control moisture and minimize waste.

Constant Research and Development

OGL cryo grinding processes are always under active development. Contact an OGL Service Rep to stay up to date on upcoming enhancements, optimizations, and new grinding options.

Call us on

+1 847.481.8264

Email us

osaka-g777@aaamachine.com