Your grind is our passion: OGL cryo grinding is here to resolve your toll processing & polymer grinding issues.

Sensitive? Low Melting Points? No Problem.

Retain the key properties of your sensitive, heat sensitive, & low melting point materials by embrittling them at cryogenic temperatures before grinding.

Soft Plastic? Rubber? Let's Do This.

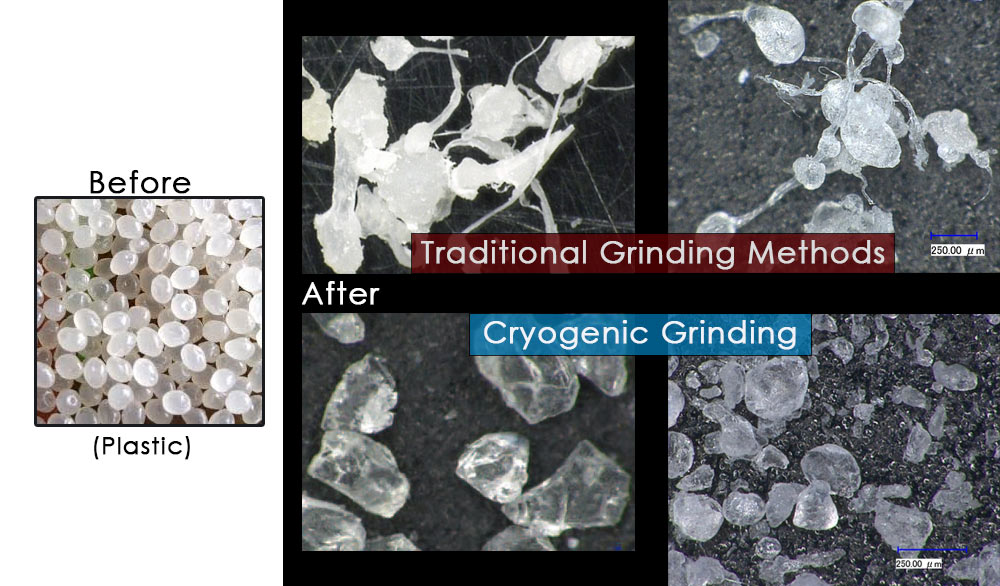

Safely grind soft plastics and rubbers that normally deform or degrade in the heat generated by traditional milling equipment

High Oil / High Moisture? We've got you covered.

Uniformly grind high-moisture or high-oil content food products in our HACCP-certified food grinding facility.

Even 3D Printing Resins are OK.

We can even custom grind novel materials like photopolymers for the latest ultra-fine 3D printing resins.

Fine, Ultra-Fine, Extreme Ultra-Fine: The OGL cryo-milling process produces your powder with little waste & consistent high quality.

Don’t Let Grinding Problems Stop You From Delivering

We're the solution to your powder production problems.

OGL’s Grinding & Milling Division is bringing the latest high-efficiency cryogenic grinding technology along with its decades of engineering know-how from Japan to the US. Whether it's a single-run order or an ongoing need for custom grinding, we can handle it.

What is Cryogenic Grinding?

Our grinding centers use liquid nitrogen produced by our OGL partner division and the very latest cryogenic freezing technology to lower the temperature of your materials to -320° F (-196° C). This allows us to grind food or polymers that can't be ground at ambient temperatures, or which degrade in heat generated by conventional milling processes.

Why use Toll Processing Services?

1. Lack of Funds

No room in your budget for new milling equipment?

2. Small Batches

Do you have a grinding job too small to justify new capital purchases?

3. Heat Sensitive Products

Problems grinding heat-sensitive materials on your existing mills?

4. Too Complex

Not enough time to develop in-house grinding expertise for an advanced new product?

Osaka Gas Liquid offers Toll Cryogenic Grinding services. This means that for an agreed toll rate OGL processes your materials at one of our state-of-the-art grinding centers.

Industry Leaders in Experience & Creativity

Work with experienced engineers utilizing finely-tuned processes for grinding a wide range of materials

Fine, Ultra-Fine, Extreme Ultra-Fine

Gain access to milling equipment that allows full grinding control down to extreme ultra-fine particle sizes

Perfect for Sensitive Materials and Low Melting Points

Retain the key properties of your sensitive, low melting point materials by embrittling them at cryogenic temperatures before grinding.

Grind Soft Plastic and Rubber Without Degradation

Safely grind soft plastics and rubbers that normally deform or degrade in the heat generated by traditional milling equipment

High Oil / High Moisture Materials Are No Problem.

Uniformly grind high-moisture or high-oil content food products in our HACCP-certified food grinding facility

High Yield / Great Waste Reduction

Reduce waste by taking advantage of our optimized grinding process that yields the narrowest possible particle size distribution

Multiple Classification Options

Specify exact sieving/classification requirements with multiple classification options available

Even 3D Printing Resins are OK

Custom grind novel materials like photopolymers for the latest ultra-fine 3D printing resins

We Solve Even the Toughest Grinding Jobs

OGL Cryo Grinding — Key Features

The Power of Liquid Nitrogen

Cooling soft, oily, or flexible materials with OGL liquid nitrogen to -320° F (-196° C) embrittles them, so they can be ground to ultra-fine particle sizes, often below 50 micron (250 mesh).

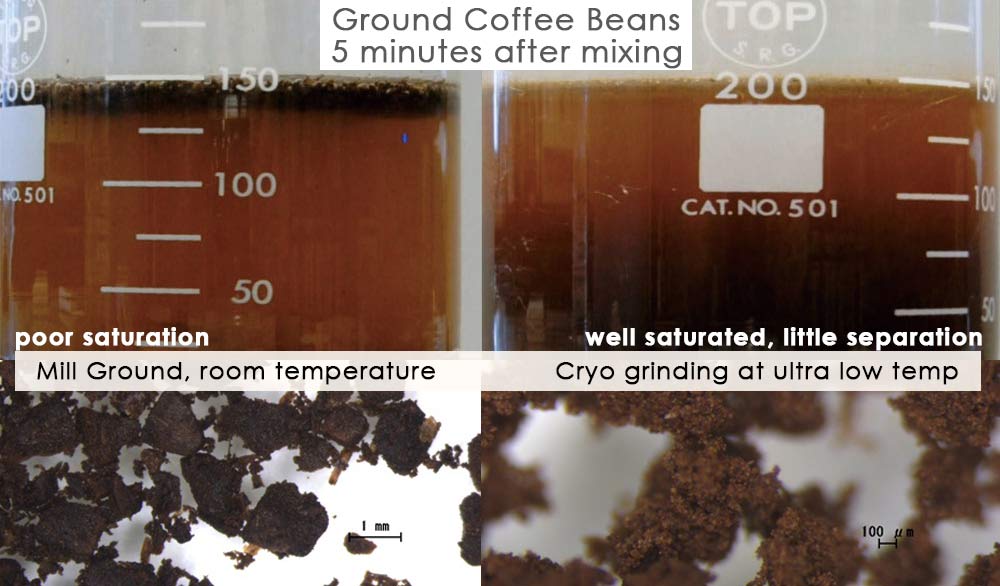

1. Ultra-finely ground particles offer superior liquid dispersion and penetration

2. Wet, oily, or soft materials can be ground at cryogenic temperatures

3. Cryogenically ground foodstuffs retain volatile flavor compounds normally lost to heat or oxidation

4. Embrittled plastics and elastomers can be ground to particle sizes with a far greater uniformity, reducing deformations and polymer ‘tails’

OGL Cryogenic Grinding & Milling Services

Osaka Gas Liquid’s Grinding & Milling Division uses liquid nitrogen critical for cryogenic grinding provided by our OGL partner division. OGL liquid nitrogen is delivered to our state-of-the-art grinding centers, which are specialized for either food or polymer grinding.

Osaka Gas Liquid’s Grinding & Milling Division

Our Grinding / Processing Specialties

- Polymers

- Foodstuffs

Get in Touch

Toll Processing by OGL: Cryo grinding (cryogenic milling) solves all your custom grinding and ultra fine powder needs.

Call us on

+1 847.481.8264

Email us

osaka-g777@aaamachine.com