Dispersion, mixing, coating, agglomeration and more

- CHOOSE YOUR TYPE: Dry mixer available in batch and continuous mixing models.

- BEATS THE COMPETITION: Best used to humidify and coat batches of powdered materials

- MORE FUNCTIONS, SMALLER FOOTPRINT: High performance high spec industrial mixer

- PROVEN RESULTS: Over 450 units in production environments around the globe!

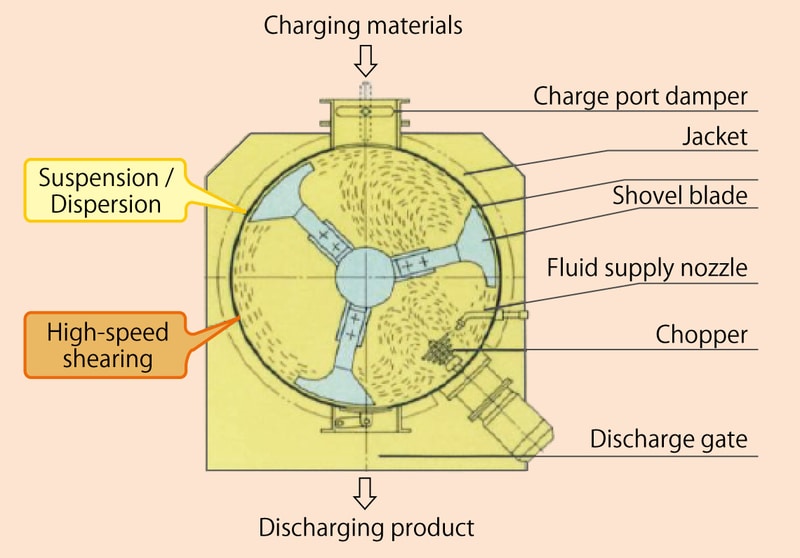

The Pam Apex mixer features 2 types of mixing actions: mixing and separating to prevent clumping and to help achieve an optimal blend of powders with an even distribution.

Combining diffusion mixing with the main blade with high-speed shear dispersion from the chopper, Pam Apex can realize a better blended mix of powders that traditional mixers just can't come close to.

With our smart design to better share processes, the Pam Apex is a great energy saver.

This mixer’s innovations have made impossible processes in various sectors possible; contact us if you’ve had powder mixing issues that need a smarter mixer to solve.

Pam Apex Mixer

Pam Apex Mixer - A high tech solution to your mixing issues

The Pam Apex mixers have a small footprint which saves floor space, a much shorter more efficient processing time which saves time and is available with various types of coatings to prevent wear and contamination*. Multiple blade variants are available so they can be suited to your specific powder processing needs and are perfect for crushing / grinding / defibration / homogenizing / drying and granulation so you can quickly use this relatively compact mixer to create your final output mixture saving money on space and extra machinery.

*Liners: We have ceramic and resin-based mixer liners to prevent wear and help ensure no metal from the unit gets into the delicate powder mix.

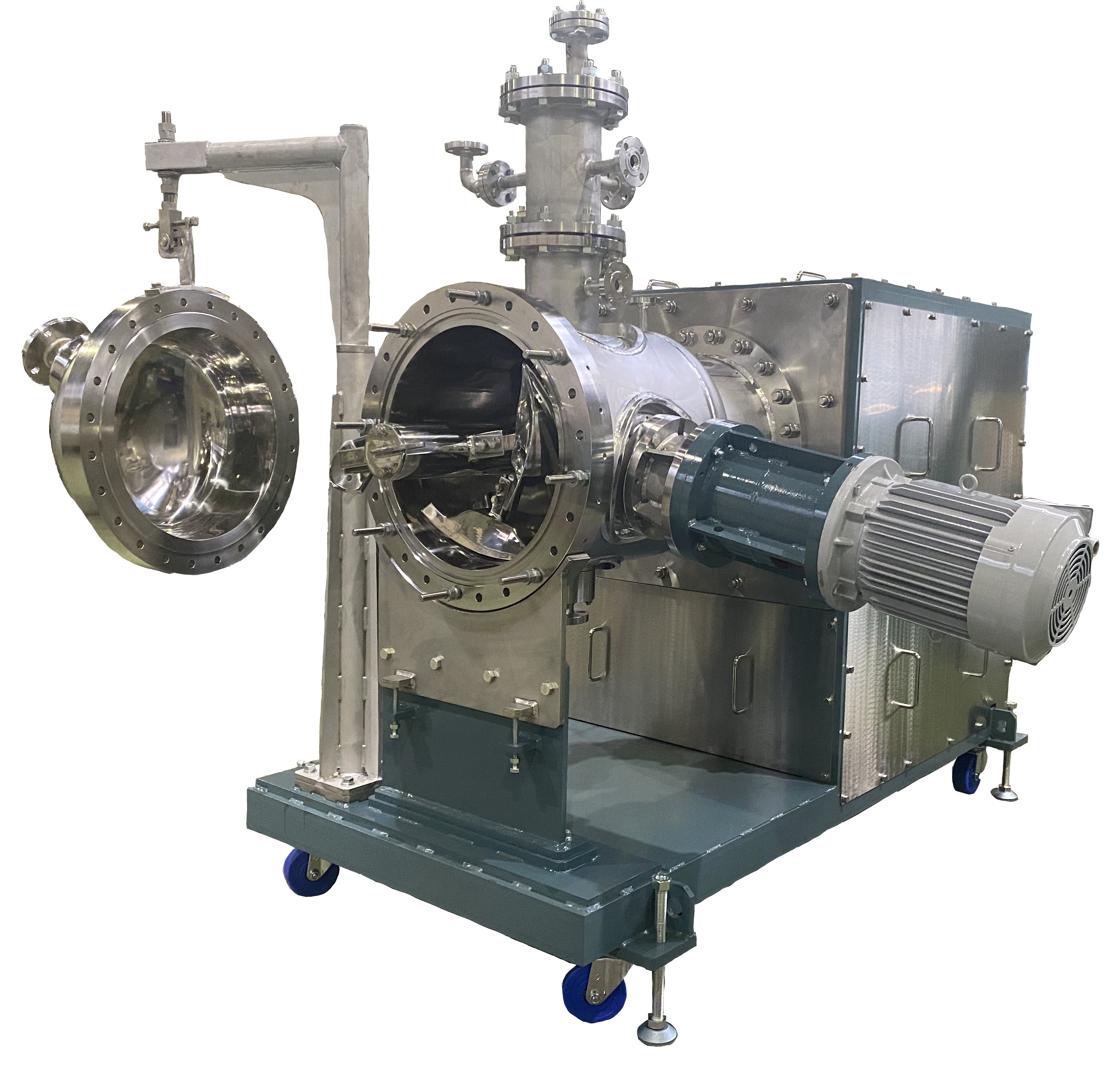

With just one unit you can mix, humidify, dry, cool, coat and more. It is specially designed to be pressure vessel compatible which means it can support vacuum drying and pressure applications. **

**Pressure vessel compatible: Other powder mixers are designed to work in regular atmospheric pressure. Pam Apex can, according to need, be used in varying pressure environments.

What can Pam Apex do that the others can’t?

Pam Apex is multi-function, they’re single function.

We can both crush and mix so that Pam Apex MIXER can pulverize lumps and clumps formed during the mixing process regardless of whether they’re formed wet or dry.

Pam Apex can do defibration mixing, others leave bulky fibers.

Quickly incorporate a small volume of additional powder uniformly into total mixture.

Dry mixing reactions facilitated by introducing hot air to the mixing process.

Granulation and liquid coating using binder liquids.

And much more!

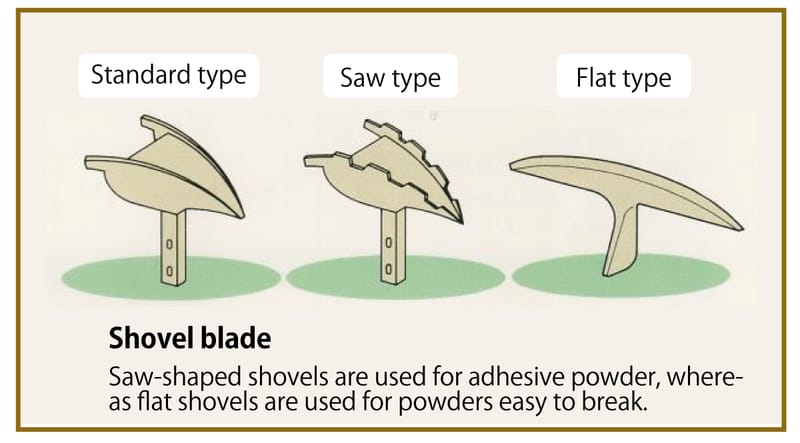

Shovel type blades

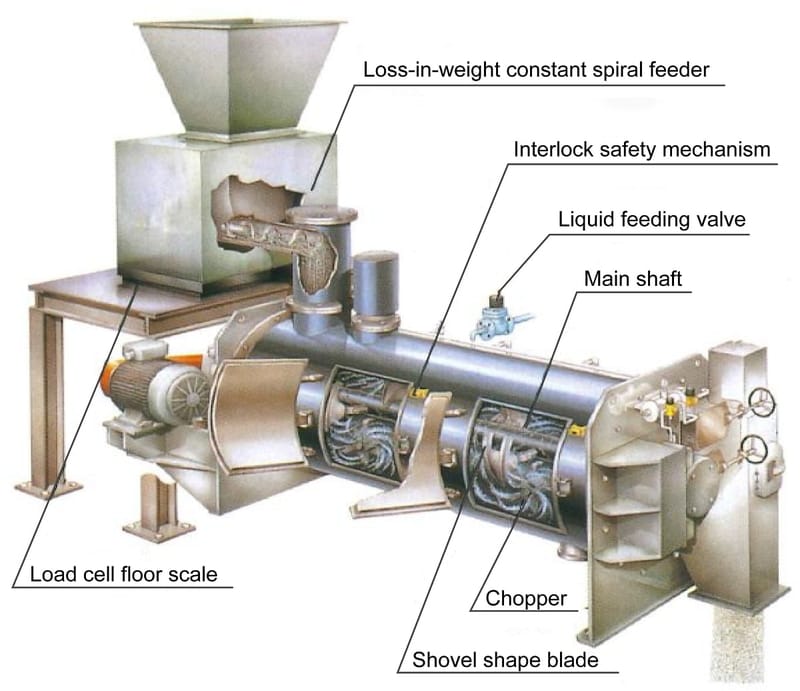

Three to eight aerodynamically designed originally designed plowshare shovel blades are arranged at regular intervals inside the mixer.

Materials are moved and agitated three-dimensionally by the suspension / dispersion function. This means that even materials with different particle diameters and gravities can be uniformly and efficiently mixed in just a short time.

Shovel blades

Saw-shaped shovels are used for adhesive / viscous / sticky powders, and flat shovels are used for powders that easy to separate.

Get to know our shovel blades;

(type utilized depends on customers’ mixing needs)

- Saw-shaped shovel blade

(for use with adhesive / viscous materials) - Half shovel blade

- Flat shovel blade

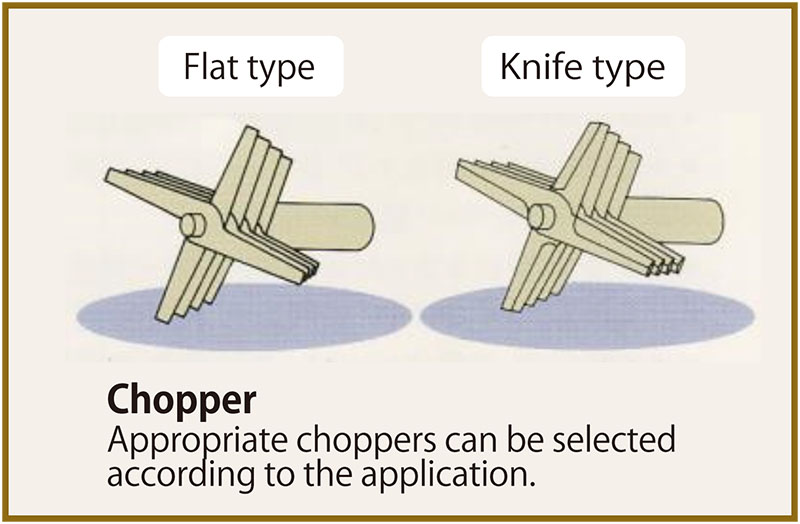

Chopper / Chopping Blades

An independently driven chopper can be installed in between the shovels.

The high rotation speeds of 1,800 to 3,600 rpm results in high-speed shearing of the powders and can also achieve:

- Defibrating / Breaking down of fibers

- Breaking up powder lumps / agglomerates

- Breaking up lumps caused by humidity / fluids

Our standard choppers are multi-stage impellers. Other styles of impeller choppers available.

- Flat type chopper

- Knife type chopper

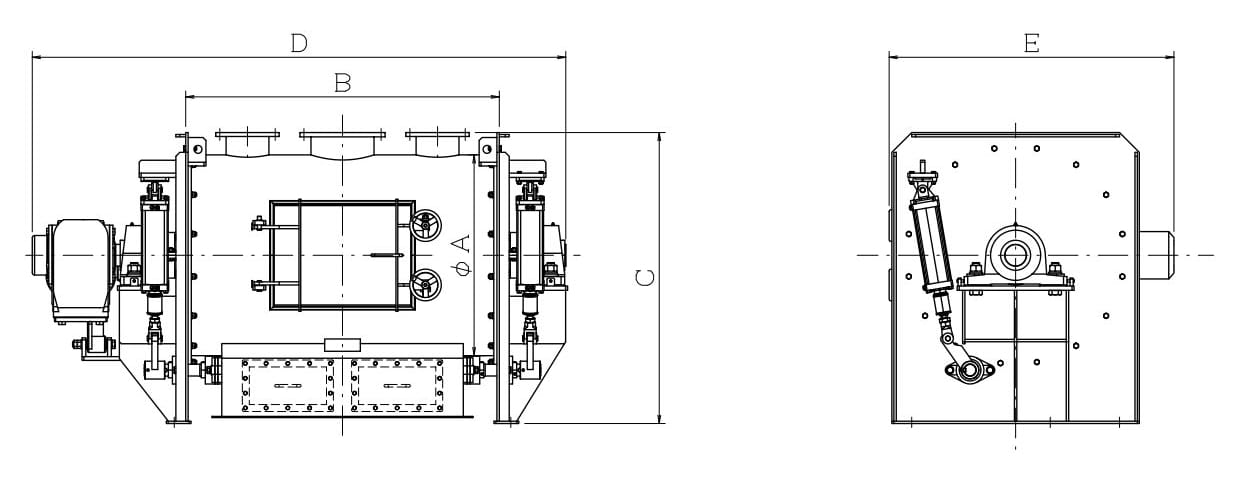

PAM APEX MIXER MODELS

Batch and Continuous

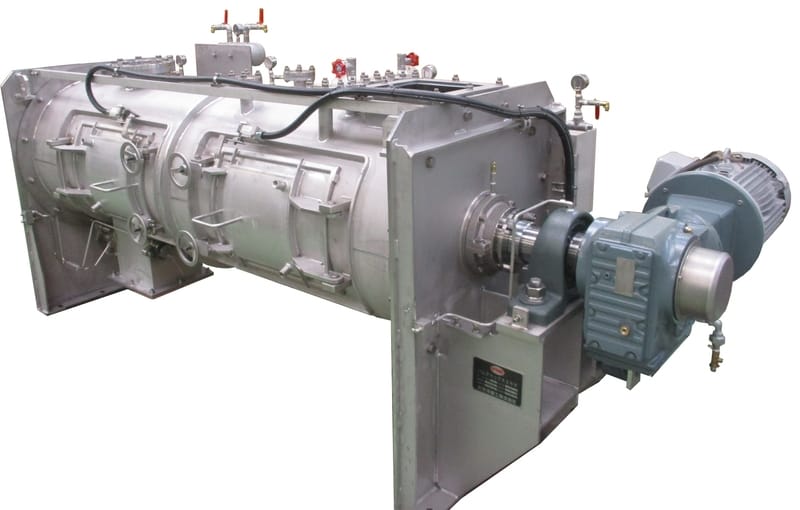

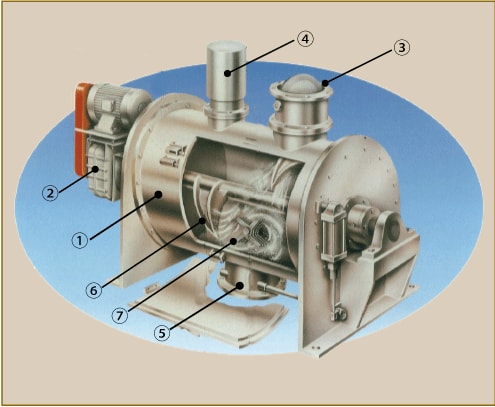

WB Pam Apex Mixer - Batch mixer

The standard batch processing model WB Pam Apex MIXER has the following components

- Transversely placed cylindrical mixing drum

- Horizontal single shaft driving section (speed reduction gear installed on shaft)

- Material charging port

- Air bleeding port / fluid replenishing port

- Air cylinder driving discharge gate and inspection door with safety device

- Plowshare type shovel blade

- Independently driven chopper

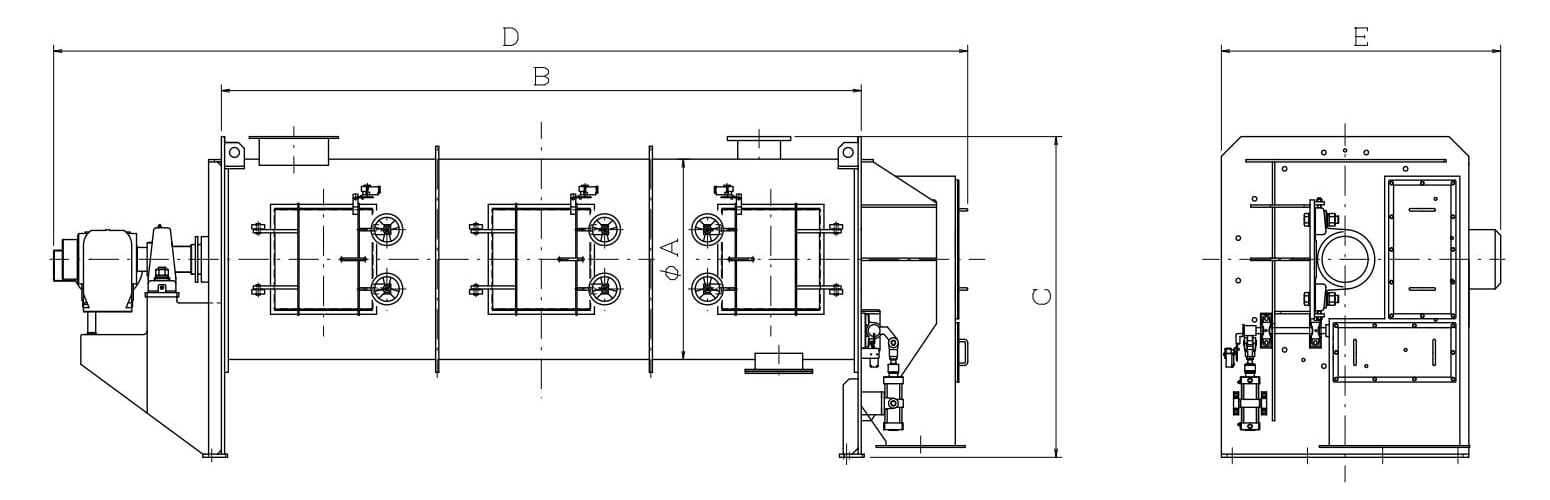

WA Pam Apex Mixer - Continuous mixer

The WA model mixer has the same basic components as the WB mixer but includes an overflow discharge port on the side.

STRENGTHS;

- A large amount of materials can be processed with amazing accuracy, economically, and with ease during a smooth unmanned automatic operation.

- Mixing precision and holding times are both adjustable so run your mixing to meet your exacting needs.

- Like the WB model, the WA model offers high-precision mixing, efficient agglomerate dispersion and liquid coating to help produce the exacting results your business needs.

Specifications by Model

WB Series Batch Mixers

Standard model sizing. Larger and smaller version also available / can be made, enquire today if you need a custom sized model

Model |

Mixer Body Capacity (liter) |

Mixing Volume (liter / batch) |

Power Required (kW) |

Dimensions (mm/inch) |

||||

|---|---|---|---|---|---|---|---|---|

A |

B |

C |

D |

E |

||||

| WB-75 | 69 | 20-48 | 2.2-3.7 | 407/16.0 | 630/24.8 | 555/21.9 | 1,050/41.3 | 485/19.1 |

| WB-150 | 136 | 40-95 | 3.7-7.5 | 508/20.0 | 750/29.5 | 730/28.7 | 1,420/55.9 | 655/25.8 |

| WB-300 | 300 | 100-200 | 5.5-11 | 608/23.9 | 1,050/41.3 | 865/34.1 | 1,750/68.9 | 900/35.4 |

| WB-600 | 600 | 200-400 | 7.5-15 | 812/32.0 | 1,150/45.3 | 1,145/45.1 | 2,100/82.7 | 1,100/43.3 |

| WB-1200 | 1,200 | 400-800 | 11-18.5 | 1,016/40.0 | 1,480/58.3 | 1,406/55.4 | 1,671/65.8 | 1,250/49.2 |

| WB-1800 | 1,800 | 600-1,200 | 15-22 | 1,216/47.9 | 1,600/63.0 | 1,680/66.1 | 2,400/94.5 | 1,151/59.6 |

| WB-2400 | 2,350 | 800-1,600 | 18.5-30 | 1,220/48.0 | 2,000/78.7 | 1,680/66.1 | 3,280/129.1 | 1,515/59.6 |

| WB-3500 | 3,500 | 1,100-2,400 | 22-37 | 1,526/60.1 | 2,000/78.7 | 2,000/78.7 | 3,300/129.9 | 1,900/74.8 |

| WB-4600 | 4,550 | 1,500-3,000 | 30-45 | 1,526/60.1 | 2,500/98.4 | 2,000/78.7 | 3,800/149.6 | 1,900/74.8 |

| WB-7400 | 7,400 | 2,400-5,000 | 37-55 | 1,818/71.6 | 2,900/114.2 | 2,330/91.7 | 4,070/160.2 | 2,200/86.6 |

| WB-9000 | 8,800 | 3,000-6,000 | 45-90 | 1,829/72.0 | 3,000/118.1 | 2,400/94.5 | 4,600/181.1 | 2,300/90.6 |

WA Series Continuous Mixers

Model |

Mixer Body Capacity (liter) |

Mixing Volume (liter / HR) |

Power Required (kW) |

Dimensions(mm/inch) |

||||

|---|---|---|---|---|---|---|---|---|

A |

B |

C |

D |

E |

||||

| WA-75 | 75 | 420 | 3.7-7.5 | 318/12.5 | 1,000/39.4 | 480/18.9 | 1,816/71.5 | 450/17.7 |

| WA-150 | 160 | 1,000 | 5.5-11 | 406/16.0 | 1,300/51.2 | 680/26.8 | 2,030/79.9 | 550/21.7 |

| WA-300 | 330 | 2,000 | 7.5-15 | 508/20.0 | 1,680/66.1 | 750/29.5 | 2,200/86.6 | 655/25.8 |

| WA-600 | 670 | 4,000 | 11-30 | 609/24.0 | 2,160/85.0 | 900/35.4 | 3,220/126.8 | 760/29.9 |

| WA-1200 | 1,300 | 8,000 | 15-45 | 812/32.0 | 2,670/105.1 | 1,170/46.1 | 3,870/152.4 | 1,100/43.3 |

| WA-2400 | 2,400 | 15,000 | 22-75 | 1,016/40.0 | 3,200/126.0 | 1,350/53.1 | 4,450/175.2 | 1,250/49.2 |

| WA-4200 | 4,200 | 25,000 | 30-110 | 1,220/48.0 | 3,820/150.4 | 1,750/68.9 | 5,120/201.6 | 1,500/19.7 |

| WA-8400 | 8,400 | 50,000 | 45-160 | 1,526/60.1 | 4,800/189.0 | 2,000/78.7 | 6,800/267.7 | 1,900/74.8 |

| WA-16000 | 16,000 | 100,000 | 55-160 | 1,829/72.0 | 6,300/248.0 | 2,230/87.8 | 8,650/340.6 | 2,300/90.6 |

* The above volume rate is calculated based on 5 min. residence time.

Use as a drying machine!

By adding a heating jacket to the outside of the drum and making the inside into a vacuum a large you now have a large area to effectively and uniformly dry powder.

STRENGTHS;

- One Pam Apex Mixer fitted with a heating jacket can carry out this entire process:Mixing → liquid addition / coating → drying → cooling → crushing / breaking up

- Only uses about 1/10th to 1/20th of the hot air that conventional dryers use.

- The efficient homogenous mixing means no uneven drying.

- Crushes and separates lumps created during the drying process.

Pam Apex Mixer - OPTIONAL PARTS / FEATURES

(Ask your Pam Apex MIXER rep if a special configuration with your exacting extras is available!)

- Heating / Cooling Jacket and heating / cooling elements inside the main shaft.

- Hardening treatments for ski shaped shovel blades and chopper blades. For example, heat treatments, overlaying, thermal spraying treatment options available.

- Half shovel or flat shovel blades.

- Air driven inlet valve (butterfly valve or ball valve)

- Automatic discharge gates. Square, round, large, or 2 gate options available.

- Meets explosion-proof specification AND can be run entirely automatically from an operation panel.

- Constant spiral feeder (loss-in-weight method) or powder metering machine for other methods.

- We also design and manufacture peripherals like metered liquid sprays, and options for lightweight powders.

INDUSTRIES AND APPLICATIONS

From mixing, dispersion, defibrating and wet coating, to granulation and drying, the range of products and industries we serve is wide and varied.

Battery Components

Homogeneous dispersion of active materials into binder solutions is the key to better batteries. Mixing, heating, drying, catalytic reaction mixing battery pastes is a specialty.

Bioengineering

Organic and non-organic powder mixing. Humidification, liquidation, granulating and drying of various materials. Heating, cooling, and effective homogenization of trace amounts of added materials / powders.

Pigments and Dyes

Even uniform mixing of fillers and liquid resins, mixing fillers with varied particle sizes effectively, powder paint manufacturing.

Resin / Adhesive

Mixing resins and inorganic substances, styrene / foam bead coating, calcium carbonate drying to create extremely advanced resin, phenol, epoxies, and sealants.

Friction Materials (Brake / Clutch Materials)

PAM APEX MIXERS help defibrate aramid fiber, carbon fiber, steel fiber, and asbestos and then mix them with resins to create friction materials.

Cosmetics / detergents

Perfect for dispersion mixing of pigments, talc and wax for cosmetics, and mixing and granulation of raw materials for powder detergents. Used in the creation of foundation, bio-detergents.

Pharmaceuticals

Mixing, granulation and drying of pharmaceutical products.

Addition / mixing of vitamin E, starch, protein preparations, CMC, ointment raw materials.

Food

Powdered and instant soup mixes, seasoning blends, cake mixes, snack and candy flavorings.

Mining / Cement

Adding moisture to slaked lime, production of cement-based mixtures, soil conditioners, solidifying materials, cement admixture, and more.

Building materials

Dispersion mixing of cement-based / gypsum-based powder and reinforcing fibers.

Raw material mixings for dry and wet interior / exterior panel / boards.

Fertilizer / Pesticide

Phosphate granulation, mixing of pesticides.

Granular fertilizers, anti-dispersion fertilizers, pesticide carriers.

Ceramics / Glass

Refractory material, ceramic powder mixing and drying.

Continuous mixing of silica sand and soda ash.

Powder Metallurgy

Graphite and metal powder mixing, uniform mixing of raw materials with a large difference in specific densities.

Environmental / Bio Sciences

Humidification and granulation of EP dust and fly ash.

Dust prevention treatment, waste materials crushing.

Wastewater Treatment

Polymer flocculants and neutralizing agents mixing, dewatered cake crushing and drying.