Since its founding in 1935, Kawata has developed a wide range of industrial technologies. Today, it is best known for its industry-leading mixers for manufacturing and laboratory use. Namely, Kawata’s lines of Supermixers, Superfloaters, and Nanopersion mixers.

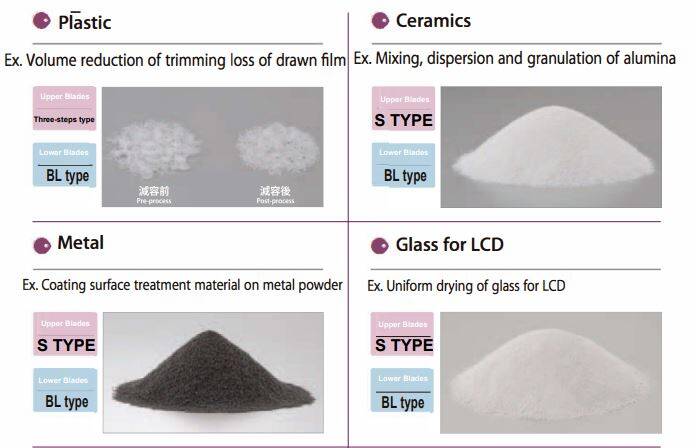

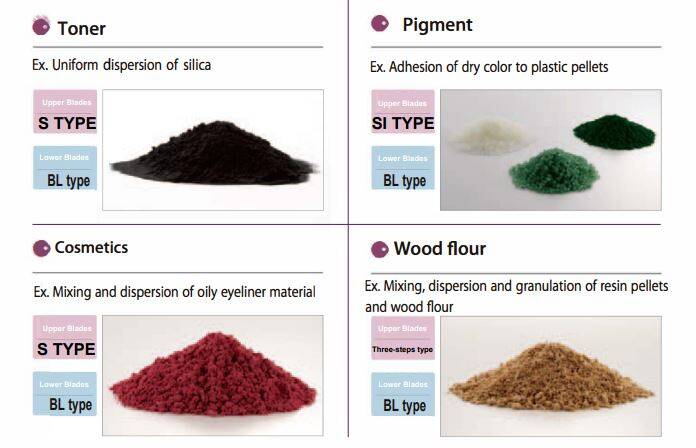

Kawata mixers are regularly used by some of the world’s leading companies in producing battery compounds, cosmetics, foodstuffs, LCD glass powder, and other powder production.

Kawata mixers take up a smaller footprint and are more efficient than other industrial mixers. They are available in a variety of designs, including both full-scale production models and desktop testing models. Kawata engineers can help you customize Supermixers to your exact specifications.

Superfloater mixers excel at mixing and wetting fillers, stabilizers, lubricants, and pigments. They can process challenging materials without requiring additional mixing or processing equipment. You also do away with mixing bowl cleaning thanks to the Superfloater’s sanitary mixing bag system.

Nanopersion Mixers are designed for grinding ultrafine particles at the nanoparticle scale. They produce high levels of surface modification in a much shorter time than traditional mixers. The Nanopersion is ideal for ultrafine mixing needs where wet mixing isn’t an option.

| Kawata Super Mixer | Conventional high speed mixer | |

|---|---|---|

| Vessel | Shallower (Depth/Dia. = 0.8) | Deep Vessel |

| Material Movement at Powder Top | ◎ Great |

△ Requires more force |

| Upper Blades | Simple | Requires many types |

| Lower Blades | Wide variety of options | Standard, limited |

| Rotor Speed for Same Mixing Performance | Lower | Higher |

| Distance Between Upper and Lower Bearing | Longer | Shorter |

| Bearing Load Balance | Half and Half (upper/lower) | More load at lower bearing than upper |

| Bearing Life | ◎ Great, very long lasting |

△ Requires more frequent replacement |

| Super Mixer High Speed Mixer | Ribbon Blender | Vertical Cone Mixer | |

|---|---|---|---|

| Material Motion | Combination of horizontal, vertical and circular motion. | Combination of horizontal and vertical motion. | Combination of horizontal and vertical motion. |

| Mixing Time

(1= Very Short, 10= Very Long) |

1 (Very Short) | 5-10 (Average to Long) | 8-10 (Long) |

| Heat Generation | Generates heat.

The shearing action of the blade naturally heats the material and makes the Super Mixer an excellent option because it eliminates the need for additional (and potentially expensive) heating equipment. |

Does not generate heat.

Unlike the Super Mixer, the Ribbon Blender does not naturally generate heat and requires additional heat sources. |

Does not generate heat.

The Vertical Screw Mixer does not naturally generate heat and requires additional heat sources. |

| Additional Heating Equipment | Usually unnecessary | Requires jacket / heat coil | Requires jacket / heat coil |

| For use in Surface Treatment | Easy | Difficult | Impossible |

| Blade Type | Upper/Lower, Replaceable | Fixed ribbon / paddle | Fixed screw |

| Cleaning | Smaller tank means less space to clean. Smaller base of tank leaves very little material behind and requires less clean-up. Removable blades make cleaning the inside of the tank much easier. Removable blades allow for better cleaning around the shaft seals. An air cylinder and opening door are available options that make cleaning the discharging chute even easier. | Larger tank means more space to clean. Larger base of tank leaves much more material behind, creating waste and more clean-up. Fixed blades make cleaning difficult because the blade could hide the sticking powder during cleaning. | Fixed blades make cleaning difficult because the blade could hide the sticking powder during cleaning. Fixed blades make it impossible to thoroughly clean the bottom shaft seals when pivot metal is used. |

| Space Requirement | Short mixing times means equipment can be very compact. | Requires a larger footprint. | Requires more ceiling height. |

| Other Features | Kawata Industrial Mixer Blades dramatically accelerate the processing rate to increase output and produce a better result. With a quicker processing time, batches can be smaller. This reduces the space requirements of the equipment that comes before and after the mixing step. | The Ribbon Blender needs longer processing time. This long mixing time requires larger batches. This increases costs and the size of equipment before and after the mixing process. | This blender needs longer processing time. The long mixing time requires larger batches. This increases costs and the size of equipment before and after the mixing process. This method uses a large screw to push materials against the walls of the tank; High-viscosity materials are likely to stick to the walls making thorough mixing difficult or impossible. |